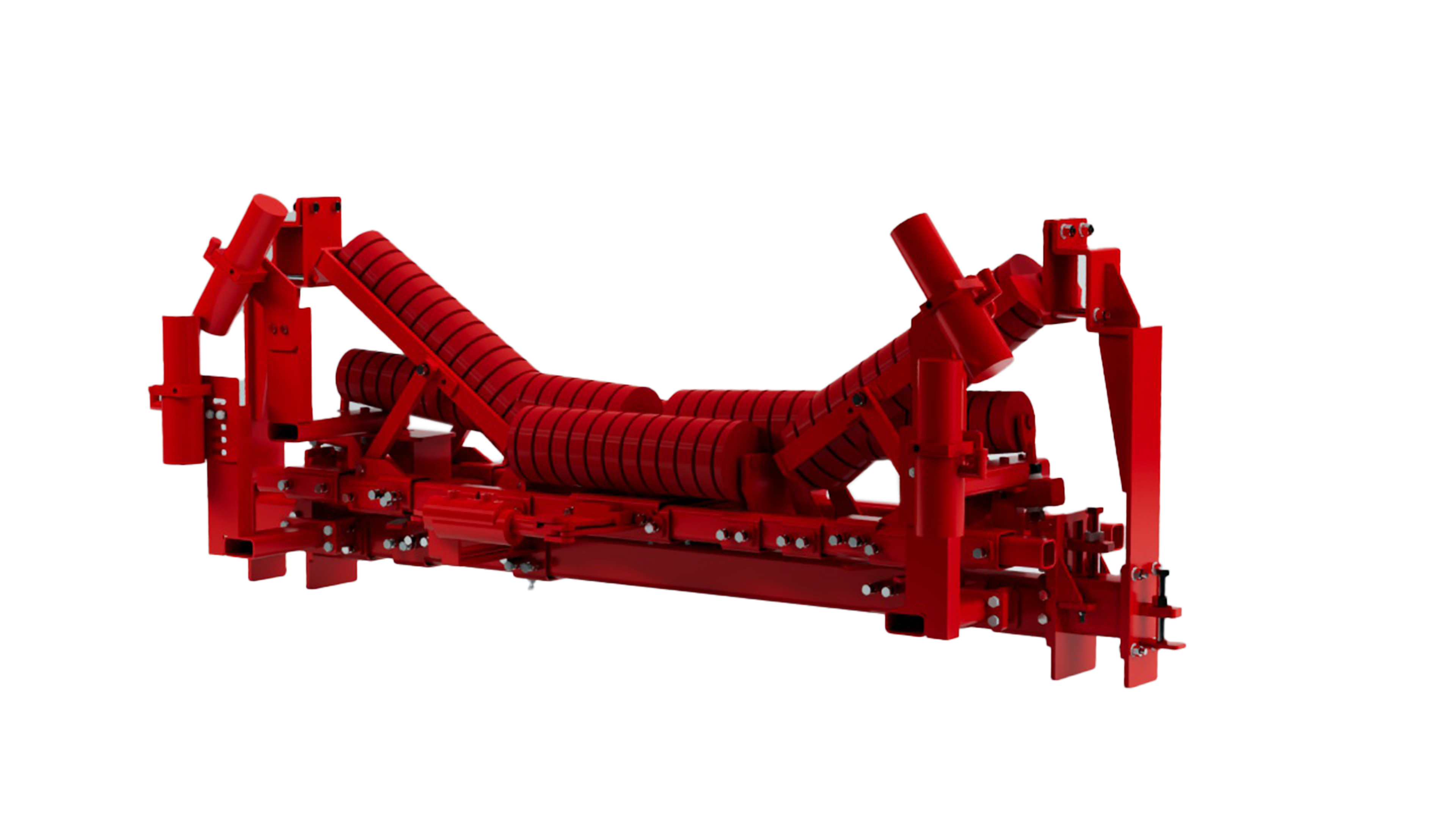

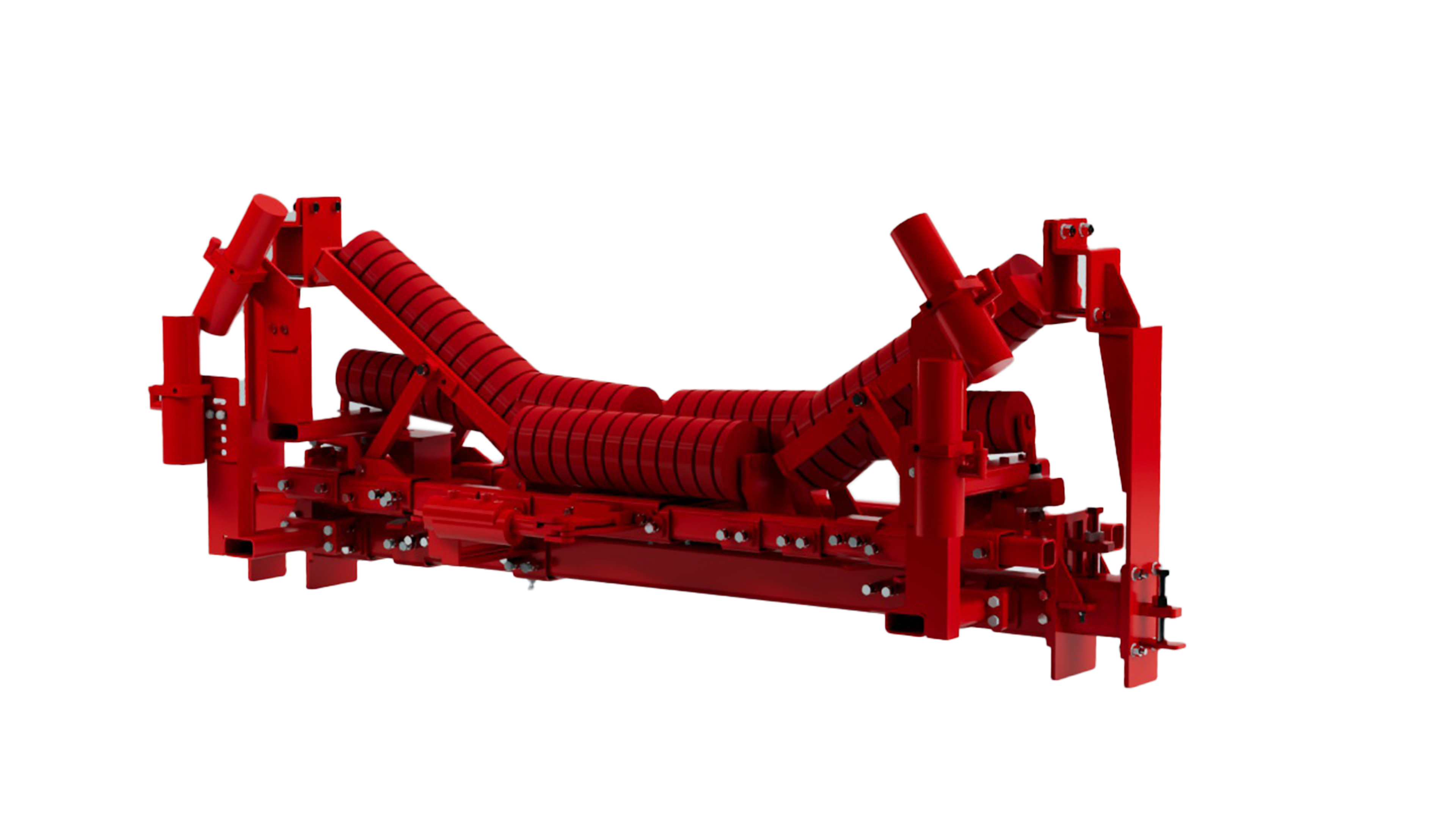

PRODUCT FEATURES

· No power source required & easy maintenance: The Hydraulic Tracker Roller Systems requires no power source, featuring a simple structure, reliable performance, and easy maintenance. It uses no electricity or electrical control components, making it suitable for explosion-proof, dusty, humid, and high-temperature environments, as well as underground and other hazardous areas with flammable or explosive materials.

· High reliability & durability: All components of the Hydraulic Tracker Roller Systems operate under extremely low load and for short durations, ensuring excellent durability.

· Enhanced driving efficiency: The driving roller is replaced with a driving vertical roller. When the conveyor belt deviates and drives the vertical roller to rotate, the vertical roller generates greater kinetic energy — thus transmitting more energy to the oil pump than the conventional driving roller.

· High correction efficiency: As soon as the belt deviates and touches the detection wheel, the Hydraulic Tracker Roller Systems activates immediately, rotating the self-aligning idler by a certain angle to quickly correct the belt.

· Key self-aligning idler positioning function: When the self-aligning idler rotates, it automatically generates an alignment force on the belt. Meanwhile, the belt exerts a reaction force on the idler, causing it to rotate back to its original position. If the idler is not braked, the alignment force disappears as it resets. The KLD logic valve group’s braking and positioning function locks the idler at an angle where the alignment force balances the deviation force, keeping the belt centered.

· Rational layout for timely correction: Along the entire conveyor line, one set of passive hydraulic deviation-adjusting roller groups (core component of the Hydraulic Tracker Roller Systems) is installed every 20-50 meters, ensuring timely correction of conveyor belt deviation.

Range of Application

The system is widely suitable for conveyor systems in industries such as mining, coal, power generation, metallurgy, ports, chemical engineering, and building materials—especially applicable to harsh working conditions including underground mines, dusty cement plants, high-temperature power plants, and explosive petrochemical workshops.