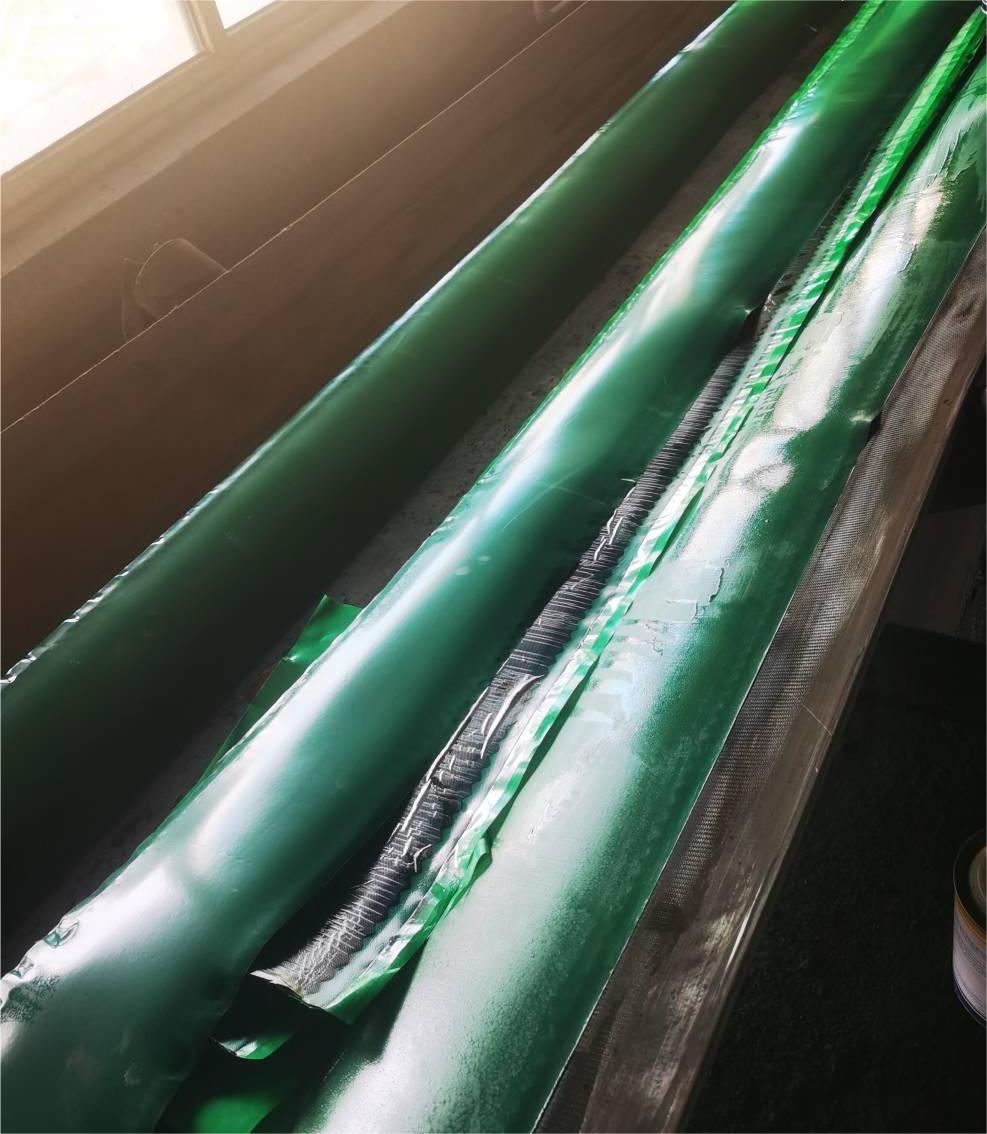

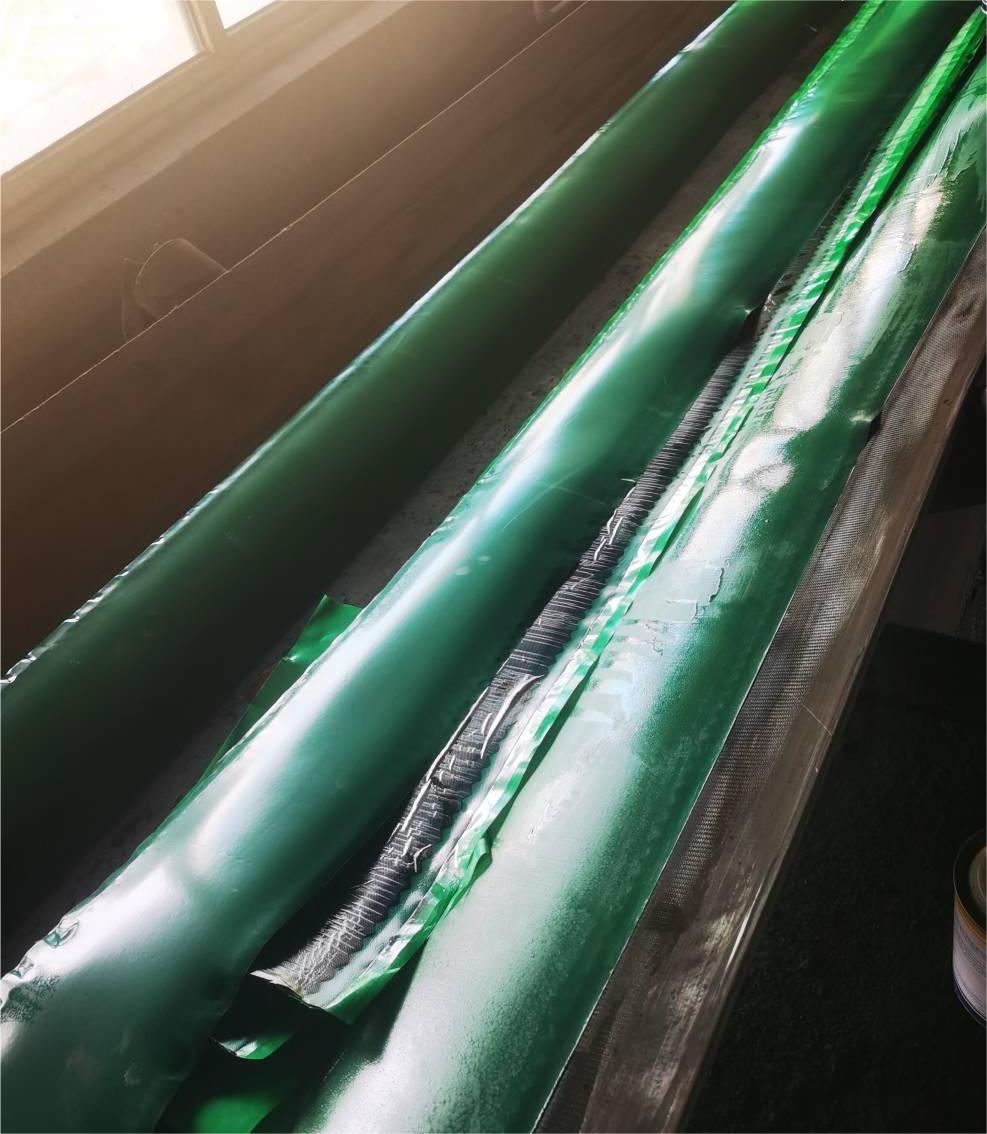

PRODUCT FEATURES

Engineered for industrial durability, our conveyor belt repair strips deliver:

Flexible, leak-proof, and equipped with wear resistance, anti-static, waterproof, self-extinguishing, and moderate oil resistance properties, ensuring robust operation in harsh mining, power, and logistics environments.

Advanced CN Bonding Technology:

Features a semi-vulcanized CN bonding layer on one side for direct, residue-free repair of damaged belt covers (no pre-grading required).

Adhesion Performance:

• 2-hour peel strength ≥ 4 N/mm (instant bonding for emergency repairs).

• 24-hour peel strength ≥ 9 N/mm (ultimate bond durability, with strength continuing to increase over time—unlike standard adhesives).

Versatile Repair Solutions: Ideal for fixing punctures, longitudinal rips, edge damage, and splice reinforcement on fabric-reinforced or steel cord conveyor belts.

SIZE :

Standard Rubber Repair Strip | 2.2*100*10000mm |

Standard Rubber Repair Strip | 3.2*220*10000mm |

Standard Rubber Repair Strip | 3.4*300*10000mm |

Standard Rubber Repair Strip | 3.4*400*10000mm |

Fabric Reinforced Repair Strip | 3.6*100*10000mm+ |

Fabric Reinforced Repair Strip | 4.6*150*10000mm+ |

Fabric Reinforced Repair Strip | 4.8*300*10000mm+ |