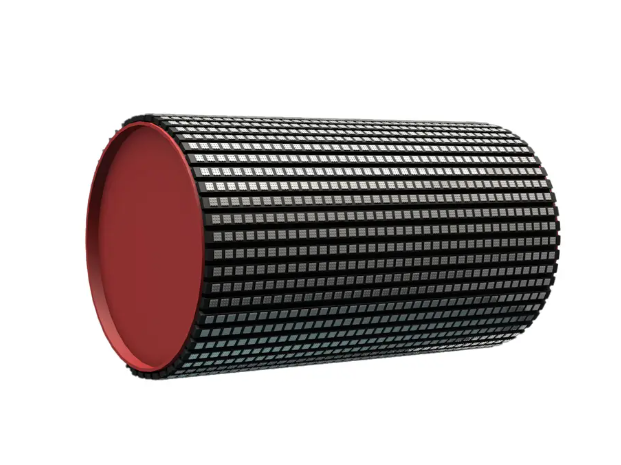

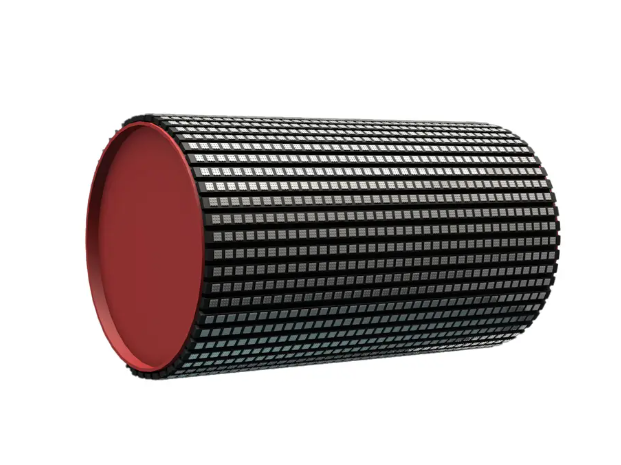

Ceramic Pulley Lagging refers to a high-performance material used to coat conveyor pulleys, particularly those subjected to extreme wear and high-impact environments. This product enhances the overall efficiency of conveyor systems by significantly reducing equipment wear and tear, thus extending the service life of critical components.

What sets Hanpeng's ceramic pulley lagging apart from traditional options is its unique CN bonding layer, which ensures strong adhesion and simplifies the installation process.

Key Features of Ceramic Pulley Lagging

45% Ceramic Coverage

The ceramic pulley lagging provides 45% ceramic coverage, offering a larger contact area between the conveyor belt and the ceramic surface, which enhances overall performance.

Circular Convex Ceramic Design

The ceramic tiles are designed with circular convex points, significantly increasing friction between the conveyor belt and the lagging, improving traction and preventing slippage.

Improved System Stability

This design improves system stability and extends the service life of both the conveyor belt and the pulley, reducing wear and tear.

Excellent Performance in Extreme Conditions

The ceramic lagging performs excellently in harsh environments, making it ideal for wet, muddy, viscous, and abrasive materials, ensuring reliable and efficient operation.

Reduced Belt Tension & Lower Energy Consumption

The unique design reduces belt tension, lowering energy consumption, minimizing conveyor system wear, and reducing operating costs.

Watch this video below to learn more about our Ceramic Pulley Lagging:

Ceramic Pulley Lagging Applications

This ceramic pulley lagging is engineered to perform under the most demanding conditions, making it suitable for the following applications:

Extreme Working Conditions

Ideal for environments where conveyor pulleys face high wear and tear, especially in industries dealing with abrasive materials.

Wet, Viscous, Muddy, and Abrasive Materials

Perfect for handling sticky, muddy, or highly abrasive materials, ensuring that the system operates efficiently in challenging environments.

High-Tension Conveyor Systems

Particularly effective for high-tension systems, where durable and reliable pulley lagging is needed to prevent slippage and maintain stability.

Drive Pulleys in Extreme Wear Conditions

Especially suited for drive pulleys exposed to severe wear, providing excellent protection and extending the lifespan of the pulley and belt.

Installation & Maintenance Benefits

The CN bonding layer simplifies the installation process, reducing the need for skilled labor and eliminating pre-treatment steps. This allows for quicker setup and lower installation costs.

With increased wear and impact resistance, ceramic pulley lagging reduces the frequency of required maintenance and component replacements, leading to significant savings in maintenance costs over time.

Improved System Stability

By improving the durability of equipment surfaces, ceramic lagging helps enhance overall system stability, leading to more reliable and efficient operations.

Performance & Economic Benefits

Ceramic pulley lagging increases the lifespan of conveyor pulleys and belts by providing superior protection against wear, reducing the frequency of replacements.

The enhanced performance of the pulley system results in reduced belt tension, leading to lower energy consumption. This contributes to overall operational cost savings.

Enhanced Conveyor Efficiency

With its wear-resistant and impact-resistant properties, ceramic pulley lagging improves the overall efficiency of the conveyor system, reducing downtime and improving productivity.

Technical Specifications & Product Options

Alumina Oxide Content: ≥95%

Mohs Hardness: >9t

Rubber Tensile Strength: >24 MPa

Rubber Elongation at Break: >880%

Product Options:

Thickness: 15mm

Width: 500mm

Length Options: 1050mm, 1250mm, 1500mm, 1600mm, 1900mm, 2100mm, 2120mm (Lengths 50mm to 100mm longer than the width of your pulley)

These options allow customers to choose the appropriate size based on their specific pulley dimensions for optimal performance.

Check out the Hanpeng product list bCelow, and select the most suitable option for your needs:

| Product Name | Ceramic Rubber Plate Size (mm) | Ceramic Area Width B (mm) |

| HP-CN-95 | 1050 * 500 * 15 | 881 |

| HP-CN-95 | 1250 * 500 * 15 | 1088 |

| HP-CN-95 | 1500 * 500 * 15 | 1205 |

| HP-CN-95 | 1650 * 500 * 15 | 1474 |

| HP-CN-95 | 1900 * 500 * 15 | 1650 |

| HP-CN-95 | 2050 * 500 * 15 | 1829 |

| HP-CN-95 | 2250 * 500 * 15 | 2004 |

| HP-CN-95 | 2500 * 500 * 15 | 2095 |

Types of Conveyor Pulley Lagging

Hanpeng offers a variety of conveyor pulley lagging options to meet diverse operational needs:

Made from high-performance ceramic materials, this type offers exceptional wear resistance, making it perfect for extreme wear environments. It enhances pulley lifespan and reduces operating costs.

Featuring a diamond-shaped rubber surface, this lagging offers superior grip and friction, ideal for environments with high friction. It reduces pulley slippage and minimizes wear.

A traditional rubber lagging that offers good wear and impact resistance, suitable for general applications. It is widely used in various conveyor systems under less extreme conditions.

FAQs

What is ceramic pulley lagging?

Ceramic pulley lagging is a high-performance material used to cover conveyor pulleys. It provides excellent wear resistance and impact resistance, helping extend the life of the pulley and improve system efficiency.

How do I install ceramic pulley lagging?

Before installation, the pulley should be ground. The lagging comes with a CN bonding layer, meaning the rubber side doesn't need to be roughened. This ensures a quick and easy installation process.

What industries benefit from ceramic pulley lagging?

Industries such as mining, paper manufacturing, steel production, and other heavy-duty operations that involve abrasive, wet, or high-tension materials benefit greatly from ceramic pulley lagging.

What is the difference between ceramic and rubber pulley lagging?

Ceramic pulley lagging provides superior wear and impact resistance, making it ideal for extreme environments. Rubber lagging, while more affordable, is typically used in less demanding applications.

How long does ceramic pulley lagging last?

With proper installation and maintenance, ceramic pulley lagging can significantly extend the life of your conveyor system components, reducing the need for frequent replacements.