In heavy industries—mining, metallurgy, coal handling, and chemical processing—conveyor belts don’t just move material; they move your uptime, safety, and operating cost. When carryback (material stuck on the return belt) starts building up, it triggers a chain reaction: spillage under the return run, dust emissions, belt mistracking, accelerated roller wear, and frequent shutdowns for cleanup. The fastest way to regain control is usually not more labor or more water, but a properly selected primary scraper installed and adjusted correctly.

1) Why Primary Scraping Matters in Heavy-Duty Conveying

A conveyor belt cleaning system typically has multiple stages, but the primary scraper is the foundation. Installed at the head pulley/discharge area, it removes the bulk of carryback right after material discharge. If the primary scraper is undersized, poorly adjusted, or not designed for your conditions, the downstream stages (secondary scrapers, plows, brushes) become overloaded and less effective. You end up paying twice—once for extra equipment, and again for downtime and maintenance.

In heavy-duty operations, carryback isn’t a minor housekeeping issue. It’s a reliability problem that affects:

Safety: spillage creates slip hazards and dust exposure

Mechanical wear: stuck material grinds rollers, idlers, and belt surfaces

Tracking performance: buildup on pulleys/rollers causes mistracking and belt edge damage

Energy consumption: extra drag and dirty components increase power demand

Downtime: manual cleanup steals hours you never get back

A well-matched heavy duty conveyor belt cleaner at the primary stage reduces carryback early, which protects the rest of the conveyor system and stabilizes maintenance planning.

2) What Is a Heavy-Duty Primary Scraper

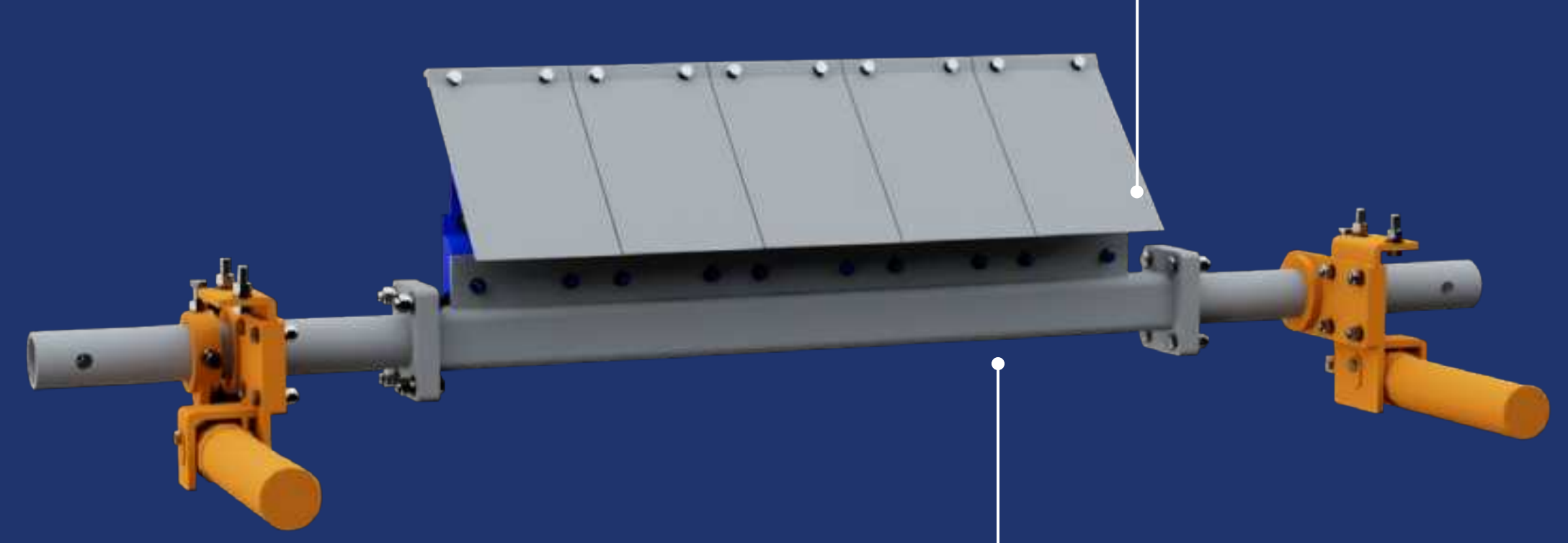

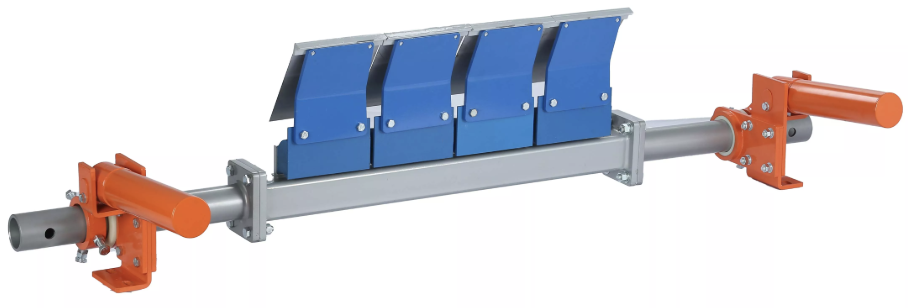

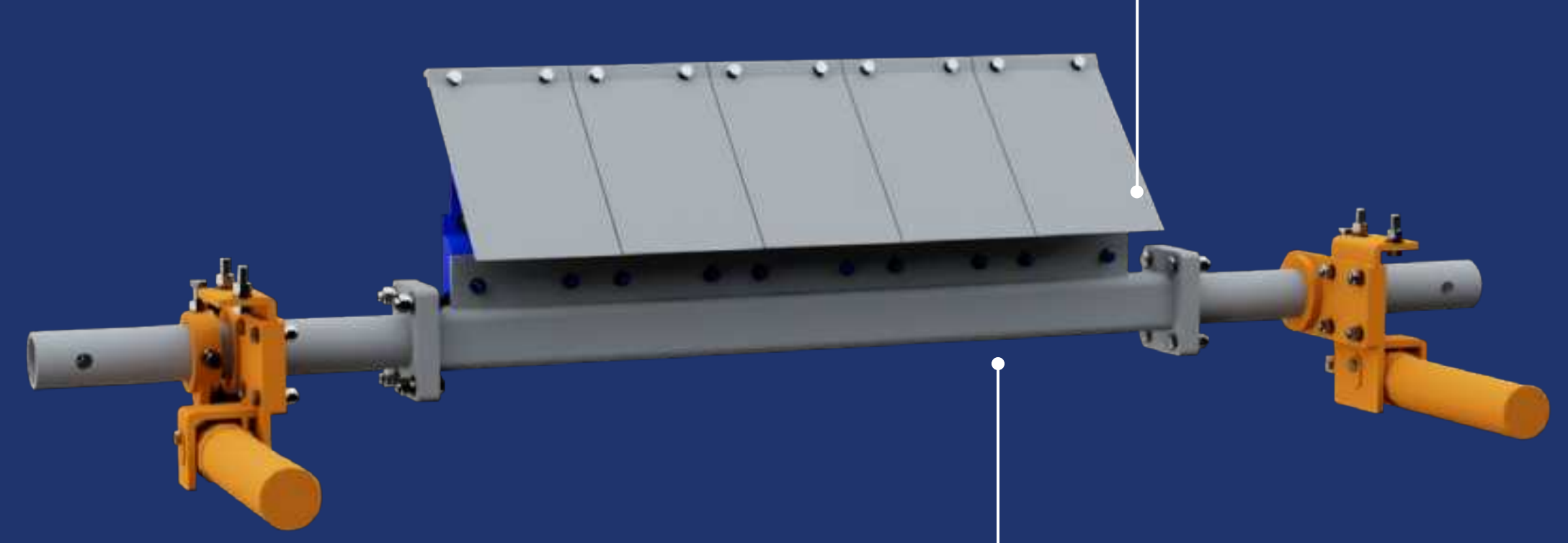

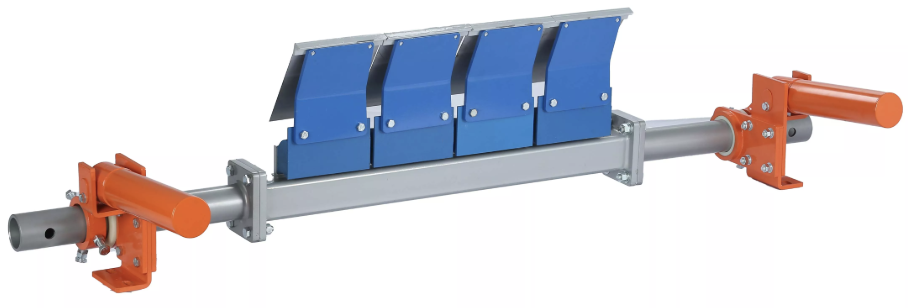

A Heavy-Duty Primary Scraper is a primary belt cleaning device engineered specifically for harsh conveying conditions—where standard belt scrapers may lose contact, wear out too quickly, or fail under shock loads. Like all primary belt cleaners, it is installed at the head pulley to remove carryback right after discharge. The difference is that a heavy-duty design focuses on maintaining stable cleaning performance under high impact, high abrasion, high load, and demanding material behavior.

The defining features of a heavy-duty primary scraper lie in its robust construction and advanced performance capabilities. Installation position is also a critical consideration for optimal performance. Positioned at an angle 15° downward from the 3 o’clock position on the front side of the head or discharge pulley, this design ensures that the scraper maintains optimal contact with the belt, even in challenging environments. To withstand abrasive fines, impact forces, and mechanical stress, heavy-duty scrapers are built using wear-resistant blade materials such as tungsten carbide and feature impact-resistant structural designs. Additionally, buffering and tensioning mechanisms are incorporated to ensure the blade stays consistently in contact with the belt surface, even as conditions fluctuate. These enhancements make it especially valuable in industries dealing with small particles, heavy loads, high temperatures, or sticky materials, where carryback is persistent and cleaning equipment is subjected to continuous stress.

In heavy industries such as mining, coal, metallurgy, and chemical processing, choosing a Heavy-Duty Conveyor Belt Cleaner at the primary stage helps reduce spillage and downtime by preventing the most common failure mode in tough sites: unstable blade-to-belt contact caused by impact, belt vibration, and rapidly changing material flow.

3) Operating Conditions and Key Specs You Must Check

Before choosing any Primary Conveyor Belt Cleaner, confirm the operating envelope. For heavy-duty applications, the PM300 Conveyor Belt Cleaner is specified by the following key parameters and working conditions:

Belt width

The PM300 Primary Scraper is designed to cover a wide range of belt widths, making it suitable for many heavy-duty conveyors. It supports 600–2400 mm belt widths, with multiple width options available to match common conveyor standards.

Belt speed

Belt speed directly affects blade-to-belt contact stability, wear rate, and the need for robust buffering and tensioning. The PM300 Heavy Duty Conveyor Belt Cleaner is rated for belt speeds up to 6.5 m/s, which covers most demanding industrial conveying lines.

Material and process conditions

The PM300 Primary Scraper is engineered for tough material behavior and process conditions, including fine/small particles, heavy-load conveying, high-temperature environments, and viscous/sticky materials—scenarios where carryback is persistent and conventional belt cleaners often struggle.

Belt splice and direction

If your belt uses vulcanized splices, the scraper must be compatible to avoid damage and maintain consistent cleaning. The PM300 is suitable for one-way operation and supports belts with cold or hot vulcanized joints, which helps it fit a broad range of heavy-duty belt configurations.

Takeaway: If you only remember one step, remember this: belt width + belt speed + material behavior are the core inputs for selecting the right PM300 configuration. Everything else refines the final setup.

4) What Makes a Primary Scraper Heavy Duty

Not all belt scrapers are built for harsh conveyors. A true heavy-duty conveyor belt cleaner typically focuses on three things: blade material, impact stability, and consistent contact pressure.

4.1 Tungsten carbide blades for abrasion and long service life

In abrasive environments (ore, slag fines, coal fines, aggregates), blade wear is often the limiting factor. Tungsten carbide blades are widely used because they offer high hardness and wear resistance, helping maintain a sharp scraping edge over longer intervals—especially under heavy load and high abrasion. A heavy-duty primary cleaner explicitly highlights a tungsten carbide blade as a durability feature for tough conditions.

4.2 Impact-resistant structure for shock loads near discharge

The head pulley zone can be violent: vibration, shock loads, fluctuating material flow, and belt surface irregularities. An industrial primary scraper may describe an impact-resistant blade design to reduce the negative effects of shock loading and to keep cleaning stable.

4.3 Independent buffer modules for stable belt contact

One of the biggest reasons scrapers fail in heavy-duty sites is inconsistent contact—either the blade lifts off (poor cleaning), or it presses too hard (belt damage and accelerated wear). Buffer modules are used to absorb shock and maintain controlled, stable contact pressure. A heavy-duty primary scraper system can include an independent buffer module to support continuous, efficient cleaning by stabilizing contact with the belt.

4.4 Corrosion protection and rugged construction

Harsh sites are often wet, acidic, salty, or chemically aggressive. Galvanized or corrosion-protected metal components are common in heavy-duty equipment to resist rust and maintain adjustability over time. (If adjusters seize due to corrosion, your easy maintenance design becomes forced downtime.)

5) Installation Overview: Placement, Alignment, and Tensioning

Even the best Heavy Duty Conveyor Belt Cleaner won’t perform if installed poorly. Primary scrapers are usually mounted just after the head pulley so the blade can scrape the belt clean as it exits the pulley.

5.1 Placement and clearance

Ensure the scraper can be mounted with adequate clearance from chute walls and structural steel.

Confirm the blade can reach the belt surface at the desired angle without interfering with pulleys or guards.

5.2 Alignment and contact angle

The goal is a stable scraping angle that removes carryback without gouging the belt. Many heavy-duty designs include mechanical structures to help you achieve and maintain the correct angle during operation.

5.3 Tensioning (keeping the blade in the sweet spot)

Tensioning determines how firmly the blade presses against the belt. Too low = carryback remains. Too high = belt wear and blade wear accelerate.

A heavy-duty system may use a dual-sided spring tensioner to keep the blade fitted against the belt while allowing controlled movement as the belt surface changes.

5.4 Adjustability for faster commissioning

In the field, time matters. Some heavy-duty primary scrapers are designed with separable support structures and an adjustable torsion bar concept to simplify installation and tuning—helping operators dial in contact angle and pressure more efficiently.

6) Maintenance Best Practices for Heavy-Duty Primary Scrapers

A good primary scraper should reduce your maintenance burden, not add to it. But every cleaner still needs inspection—especially in heavy-load applications.

Weekly/shift inspection checklist (typical)

Blade edge condition (chips, uneven wear, rounding)

Contact consistency across belt width (no clean stripe gaps)

Tensioner position and spring condition

Fasteners and mounting stability (vibration can loosen hardware)

Build-up around the mounting zone (can distort blade alignment)

Retension vs. replace

Retension when cleaning performance drops but the blade edge is still usable

Replace when the blade is worn beyond effective scraping geometry, or when segments/modules show damage

Keep belt protection in mind

Over-tensioning is one of the most common mistakes. Your maintenance team may be tempted to crank it tighter to improve cleaning quickly, but that often shifts costs from carryback cleanup to belt replacement. Use controlled adjustment and monitor wear patterns.

7) Application Examples: Matching Scraper Design to Material Behavior

Sticky / viscous materials

Sticky material tends to smear rather than fall off. A heavy-duty primary scraper designed for viscous conditions typically benefits from stable contact and shock absorption—buffering helps keep the blade engaged consistently rather than bouncing.

Abrasive fine particles

Fine abrasive carryback can act like sandpaper on both blade and belt. Tungsten carbide blades are a common choice to extend service life in abrasive systems.

High-temperature conveying

Metallurgy and slag handling demand materials and structures that remain stable in elevated temperatures. Heavy-duty systems are often positioned as appropriate for high-temperature environments such as metallurgy applications.

High-impact loading at discharge

If your chute discharge is turbulent or your belt sees shock loads near the head pulley, impact-resistant structures and buffer modules become particularly valuable for stability and continuous cleaning.

8) Selection Checklist

If you want accurate sizing and a fast quotation for a Primary Scraper / Heavy Duty Conveyor Belt Cleaner, prepare the following:

Belt width (mm) — e.g., 600–2400 mm range is common for heavy-duty models

Belt speed (m/s) — check if you are near high-speed limits such as 6.5 m/s

Material behavior — sticky/viscous, abrasive, wet, hot, fine particles

Industry/process — mining, coal, metallurgy, chemical, etc.

Head pulley diameter — impacts mounting geometry and angle

Belt splice type — cold/hot vulcanized splice compatibility may matter

Installation space constraints — chute layout, guards, structure

Environment — corrosion, moisture, dust load, chemical exposure

Pro tip: If you’re unsure about anything, share photos of the head pulley zone and existing cleaner mounting points. It speeds up engineering recommendations dramatically.

9) Conclusion

A heavy-duty primary scraper is one of the highest ROI upgrades you can make to a conveyor system—because it tackles carryback at the source. For harsh conveying conditions, look for the features that actually protect performance over time: tungsten carbide wear surfaces, impact-resistant geometry, and buffered designs that maintain stable contact under shock loads.

If you’re evaluating options, the simplest next step is this:

Send us your belt width, belt speed, material type, and head pulley photos.

We’ll recommend a suitable primary scraper / heavy duty conveyor belt cleaner configuration (and in the article we can introduce the specific model—such as PM300—based on your operating conditions) and provide a quotation with selection support.