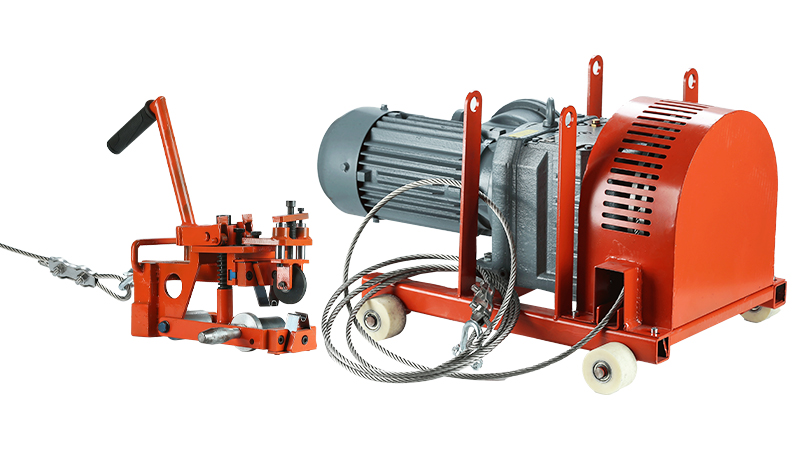

Design Features

· Reduces steel cord belt stripping time with large-area stripping, lowering labor intensity

· Simple operation, lightweight, easy to carry, transport and store

· Convenient blade replacement

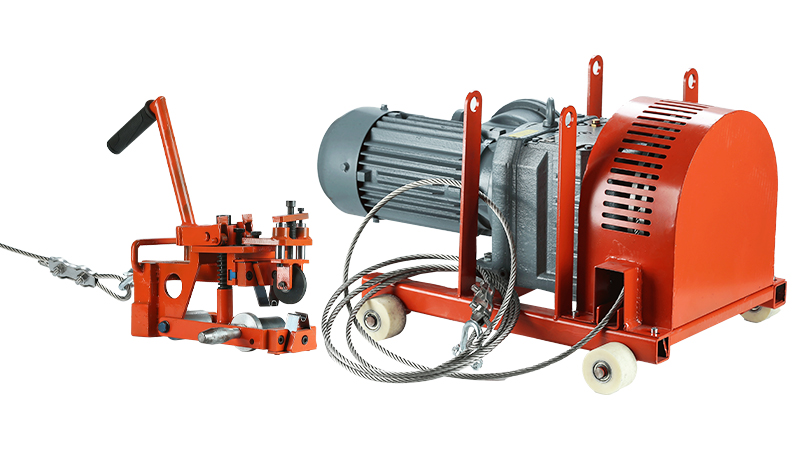

Technical Specifications

· Motor power: 1.5KW

· Working voltage: 380V

· Line speed: 0.3m/s

· Steel cord diameter range: φ4.9mm ~ φ13.2mm

· Cable spacing: ≤25mm

· Suitable conveyor belt rubber thickness: Total ≤43mm (25mm on carrying surface, 12mm on non-carrying surface)

Applications and Benefits

Designed to prepare steel cord conveyor belts for vulcanized splicing by separating steel cords from rubber, it suits various industries including power plants, mining, steelworks, wharfs, and petrochemical sectors.

Ideal for use in confined spaces and diverse splicing scenarios, it simplifies operation, shortens working time, and reduces labor intensity—delivering efficient performance for belts meeting the above specifications.