Belt conveyor systems are the backbone of material handling in industries such as mining, agriculture, and manufacturing. A critical component of these systems is the Belt Cleaning Systems, which ensure efficient operation by removing residual material from conveyor belts. Among these systems, Primary and Secondary Belt Cleaners play distinct yet complementary roles. Understanding their differences is essential for optimizing conveyor performance, reducing maintenance costs, and extending belt life.

In this article, we delve into the technical and functional disparities between primary and secondary cleaners, explore their applications, and highlight the advantages of modern solutions like the Hanpeng HP-H1 Secondary Belt Cleaner. With a focus on innovation and durability, this article also aligns with the latest industry trends, emphasizing efficiency, sustainability, and adaptability.

The Role of Belt Cleaning Systems in Conveyor Operations

Belt Cleaning Systems are engineered to address the persistent challenge of material carryback—residual particles that adhere to conveyor belts after discharge. Left unchecked, carryback causes:

Belt misalignment

Increased wear and tear

Safety hazards (e.g., slippage, material buildup)

Higher operational costs due to frequent maintenance

To mitigate these issues, Primary and Secondary Belt Cleaners work in tandem. Let’s break down their roles.

Primary Belt Cleaner – The First Line of Defense

Function and Design

A Primary Belt Cleaner is installed at the conveyor’s head pulley, where the bulk of material is discharged. Its primary function is to remove large quantities of residual material immediately after the discharge point. Key features include:

Blade Material: Often polyurethane or tungsten carbide for durability.

Installation Angle: Positioned to scrape against the belt’s direction.

Pressure Adjustment: Ensures optimal contact without damaging the belt.

Applications

Primary cleaners excel in high-volume, coarse-material environments, such as mining or aggregate processing. However, they are less effective against fine or sticky residues, which necessitates the use of a Secondary Belt Cleaner.

Secondary Belt Cleaner – Precision in Residual Removal

Function and Design

The Secondary Belt Cleaner is typically installed further along the return strand of the conveyor, addressing finer particles that evade the primary cleaner. Its design focuses on precision and adaptability:

Blade Flexibility: Adjustable blades conform to belt imperfections.

Material-Specific Solutions: Tailored for sticky, wet, or abrasive residues.

Enhanced Durability: Built to withstand harsh conditions like high-speed wear and impact.

Key Differentiators from Primary Cleaners

| Feature | Primary Cleaner | Secondary Belt Cleaner |

| Installation Location | Head pulley | Return strand (post-primary cleaner) |

| Target Material | Bulk, coarse residues | Fine, sticky, or adhesive residues |

| Blade Pressure | High pressure | Moderate to low pressure |

| Material Compatibility | General-purpose | Specialized (e.g., coal slurry, peat) |

Why Secondary Belt Cleaners Are Critical for Modern Operations

With industries increasingly handling adhesive or moisture-laden materials (e.g., coal slurry, peat), Secondary Belt Cleaners have evolved to address unique challenges:

Adaptability to Harsh Conditions: Modern secondary cleaners, like the Hanpeng HP-H1, are engineered for extreme environments, including high-speed belts (up to 10m/s) and temperatures ranging from -40°C to 120°C.

Enhanced Cleaning Efficiency: Advanced blade designs and materials reduce carryback by over 90%, minimizing downtime.

Sustainability: By reducing material waste and energy consumption, secondary cleaners align with global sustainability goals.

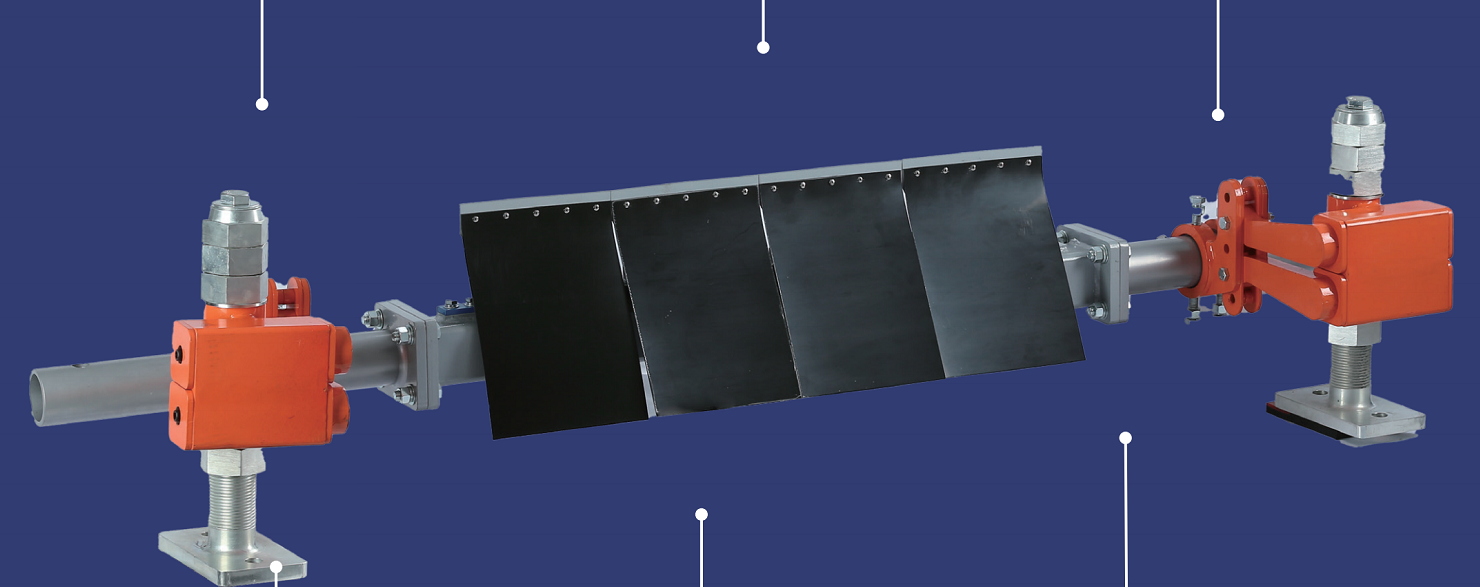

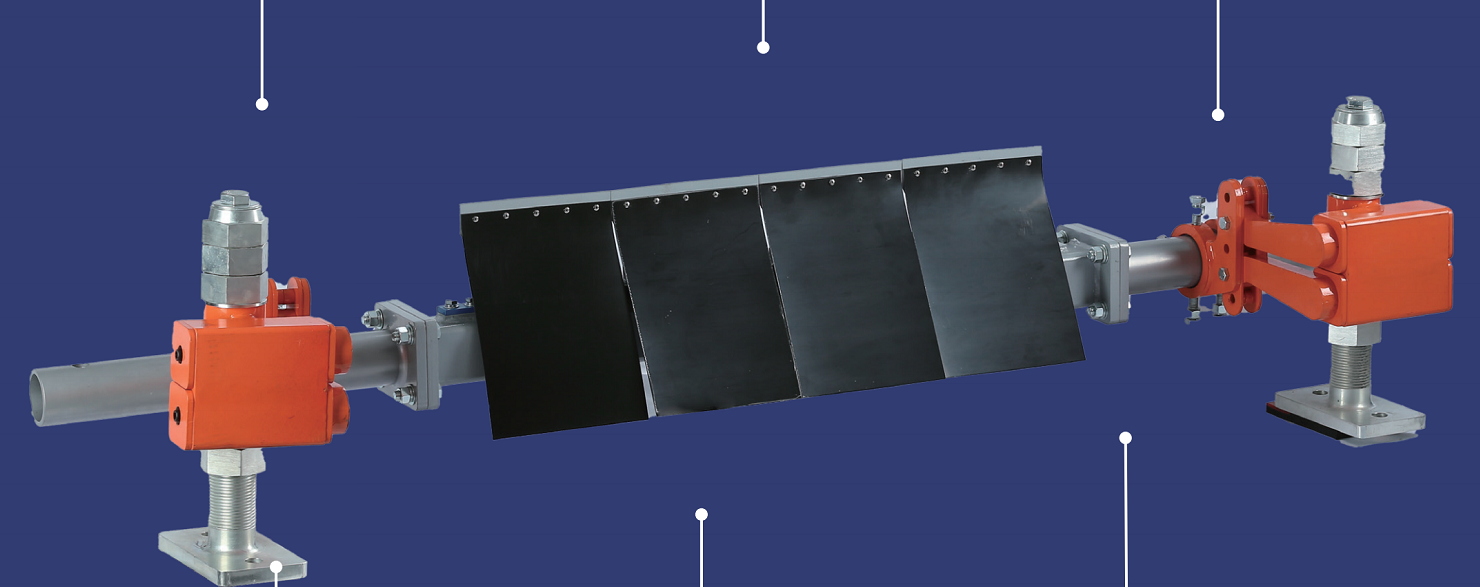

Spotlight on Hanpeng HP-H1 Secondary Belt Cleaner – Innovation Meets Durability

Hanpeng’s HP-H1 Secondary Belt Cleaner exemplifies cutting-edge engineering tailored for diverse industrial needs. Below, we explore its standout features and applications.

Range of Application

The HP-H1 is versatile, making it ideal for:

General to Extreme Conditions:

Water-saturated environments.

Strong adhesive materials (coal slurry, peat).

High-speed wear (up to 10m/s) and impact-prone settings.

Functionality as a Primary Cleaner in bidirectional operations.

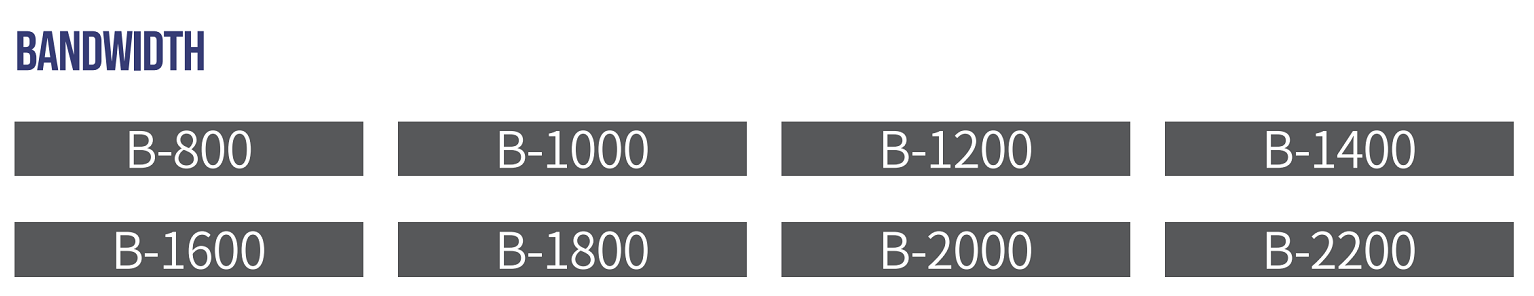

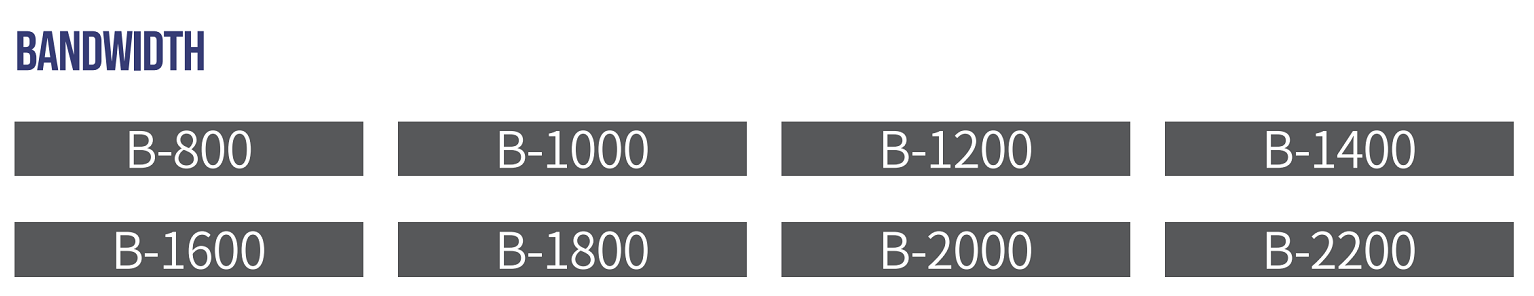

Bandwidth Compatibility: 600–2400mm (see table below).

Temperature Resilience: Effective in cold or hot vulcanized joint conveyor belts.

Bandwidth Options

Technical Advantages

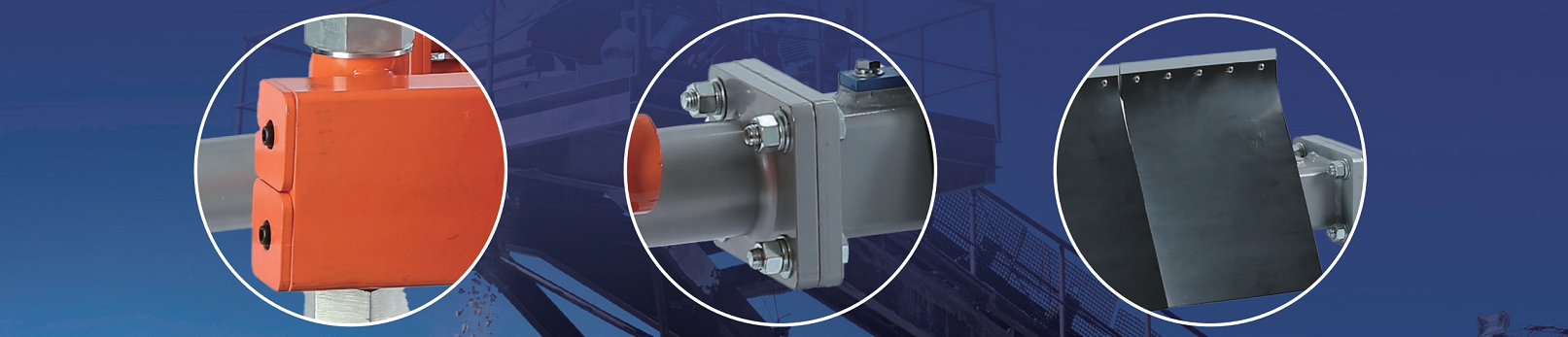

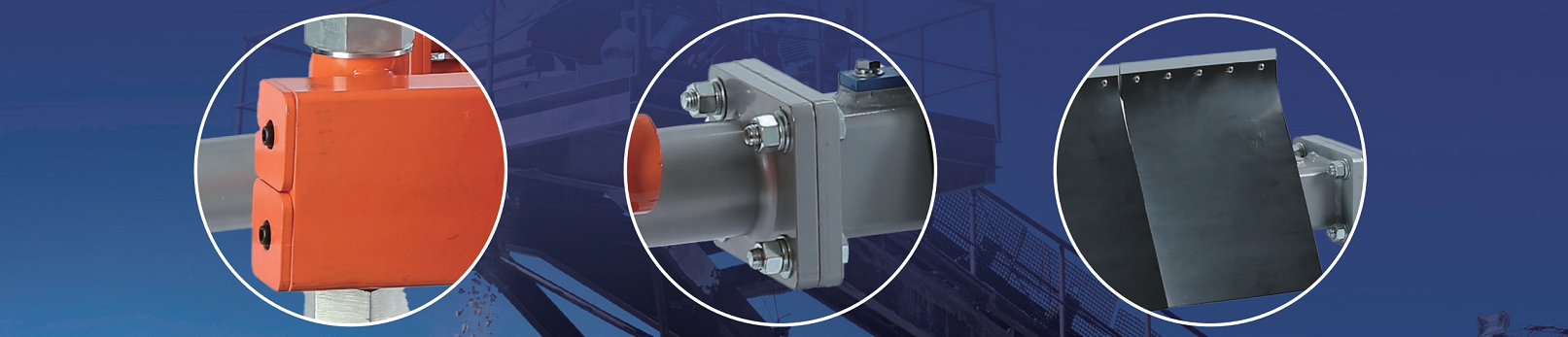

1. Individual Blade Adjustment

Each blade can be adjusted vertically to maintain optimal contact with the belt, ensuring consistent cleaning performance even as the belt wears.

2. High Wear-Resisting Tungsten Carbide Blades

The blades are crafted from tungsten carbide alloy, offering exceptional wear resistance and a lifespan up to 3x longer than conventional materials.

3. High Elasticity Rubber Modules

Every blade is supported by an independent high elastic rubber module, providing localized impact resistance and reducing stress on the blade structure.

4. Double Buffer Elastic Compensation

A patented double buffer elastic compensation device allows the holder to rebound instantly after impact, enhancing overall durability in high-vibration environments.

5. Modular Installation

The split main and auxiliary support structure simplifies installation. Tension is easily adjusted via support seat screws, ensuring a perfect blade-to-belt fit.

6. PE Fender Design

A smooth PE fender prevents material buildup around the cleaner, reducing corrosion risk and maintaining scraping efficiency.

Aligning with Industry Trends – The Future of Belt Cleaning

The demand for Secondary Belt Cleaners is surging due to:

Automation: Integration with IoT for real-time pressure and wear monitoring.

Material Innovation: Development of hybrid blades for multi-condition use.

Sustainability: Cleaners that reduce energy use by minimizing belt friction.

Hanpeng’s HP-H1 addresses these trends through modularity, durability, and adaptability, making it a future-proof investment.

[Watch the video to learn more about the HP-H1 Secondary Belt Cleaner]

Conclusion

While Primary Belt Cleaners handle bulk material removal, Secondary Belt Cleaners like the Hanpeng HP-H1 are indispensable for precision cleaning in challenging environments. By investing in advanced systems, industries can achieve:

For operations requiring resilience against water, adhesive materials, or high-speed wear, the HP-H1 stands out as a leader in Secondary Belt Cleaner technology. Its innovative design, coupled with Hanpeng’s engineering expertise, ensures optimal performance across diverse applications.