The chute rubber ceramic liner is high - performance protective equipment designed to improve the wear resistance and stability of conveyor belt chute systems, prolonging the lifespan of equipment and reducing the costs of maintenance. We offer a variety of specifications and sizes of liners, which are custom - made to meet customer needs, ensuring optimal fit and performance, and delivering greater value and efficiency to your production lines.

HP-WP-35/75

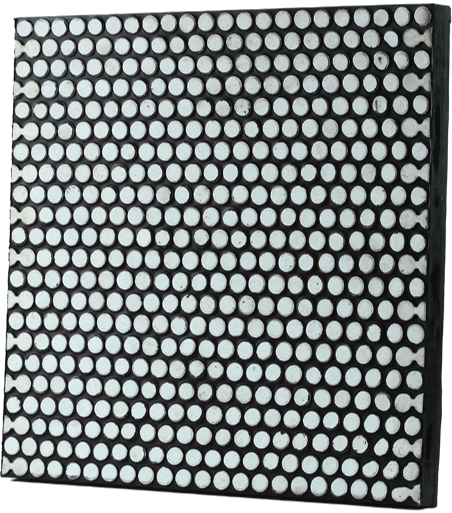

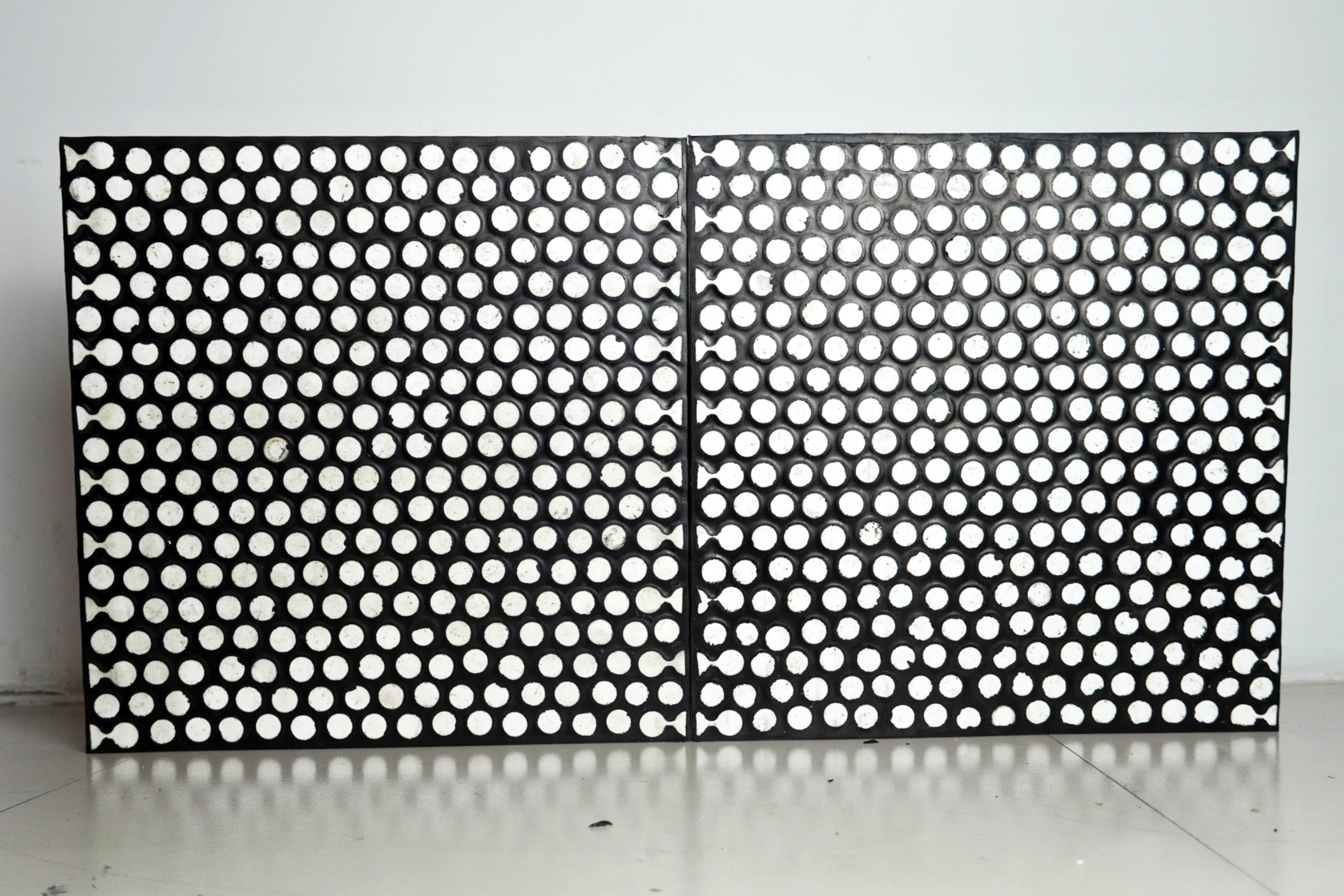

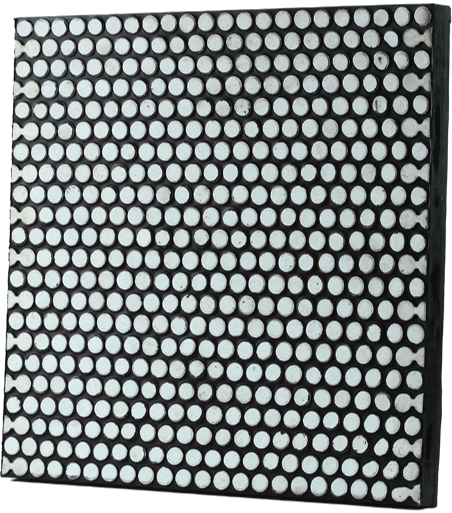

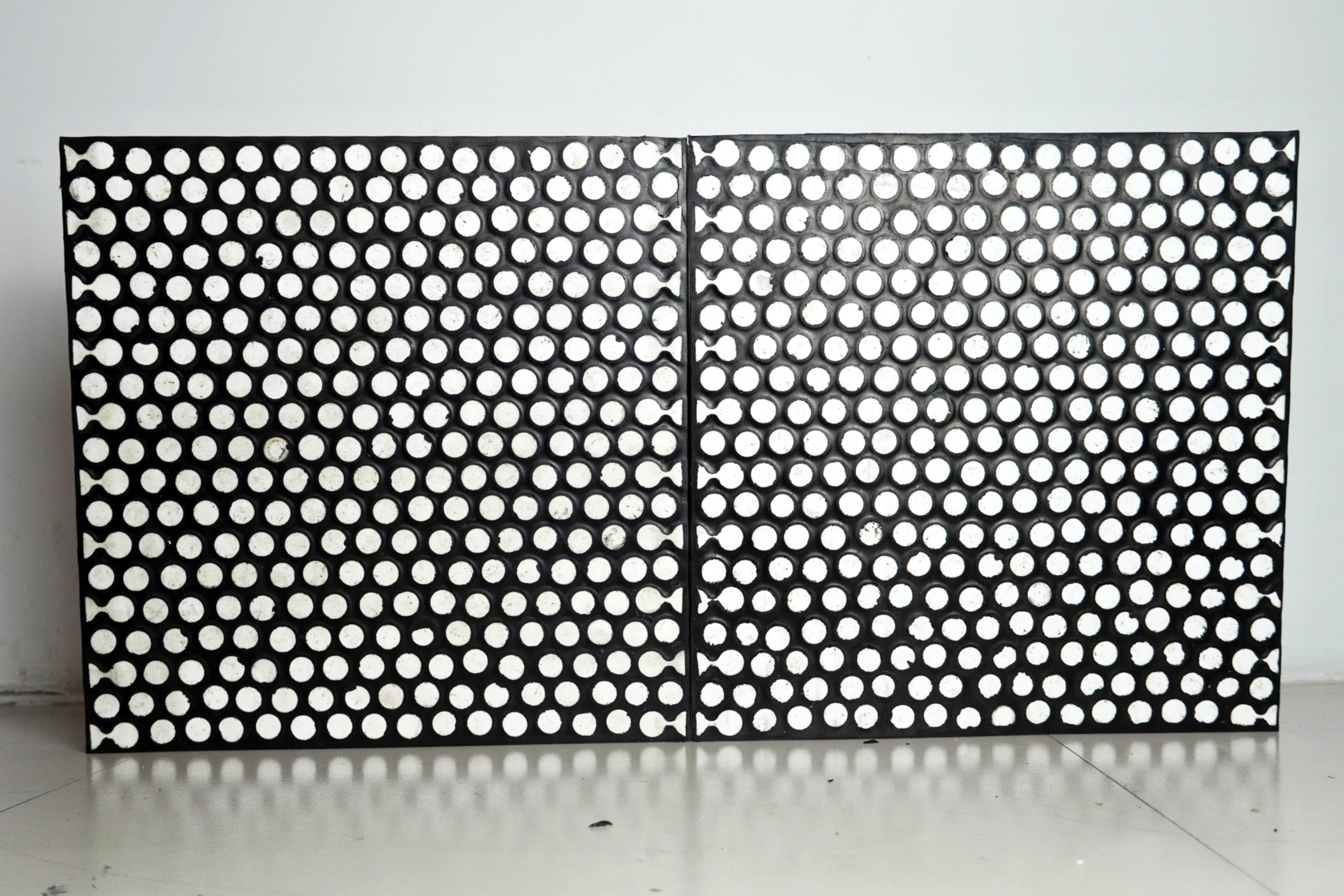

CERAMIC RUBBER LINER

PRODUCT FEATURES AND ADVANTAGES

1. PROPERTIES:

Highest abrasion-resistance: Made from high-quality alumina (Al₂O₃) ceramics, ensuring exceptional wear resistance.

Absorption of impact energies: Reduces damage caused by material impact.

Easy, flexible, and fast application: Secure fastening and simple installation process.

Reduces operating costs: Durable and long-lasting, minimizing maintenance and replacement expenses.

Long service life: Increases the efficiency and lifespan of your equipment.

Easy replacement: Modular design allows for quick and hassle-free replacement.

Good resistance against weather: Suitable for various environmental conditions.

2. AREA OF APPLICATION:

Lining against extreme wear: Ideal for high-speed abrasion environments.

Lining of material transfer stations: Suitable for low-impact angles.

Versatile applications: Used in pipelines, vibratory feeders, cyclones, skips, bunkers, chutes, loading points, slides, hoppers, silos, and more.

3. RANGE OF APPLICATION:

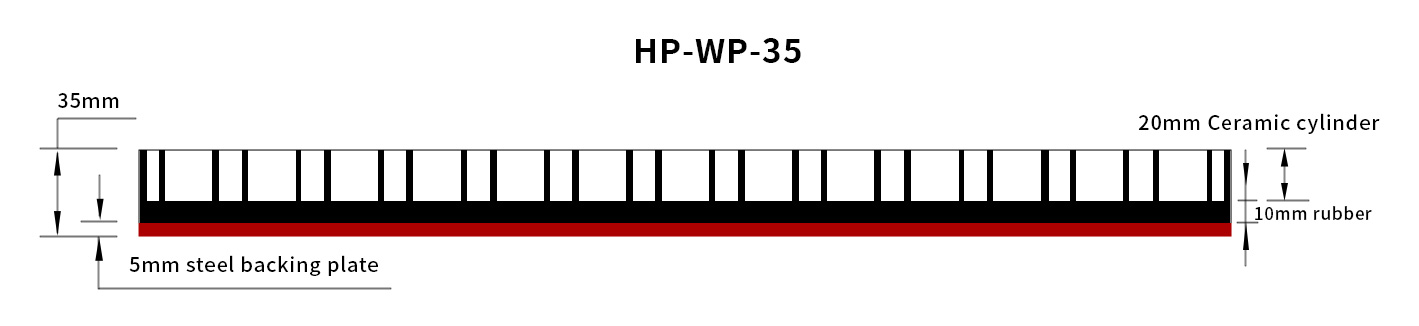

HP-WP-35/75: A composite construction of highly wear-resistant 92%-Al₂O₃ ceramic tiles hot-vulcanized in special rubber. Designed for simple to medium-duty applications in mining, gravel, sand, stone-breaking mills, and other industrial sectors.

Metal layer hot-vulcanized: Enables easy fitting to application areas using stud bolts.

TECHNICAL PARAMETERS

Alumina content: ≥ 92% (HP-WP-35/75)

Density: ≥ 3.6 g/cm³

Ceramic Rockwell hardness: ≥ 85 HRA

Compressive strength: ≥ 850 MPa

Wear volume: ≤ 0.06 cm³

Bonding strength between ceramic and rubber: ≥ 6 MPa

PRODUCT SPECIFICATIONS

Product Name | Model | Thickness | Ceramic Tile Dimensions | Packaging |

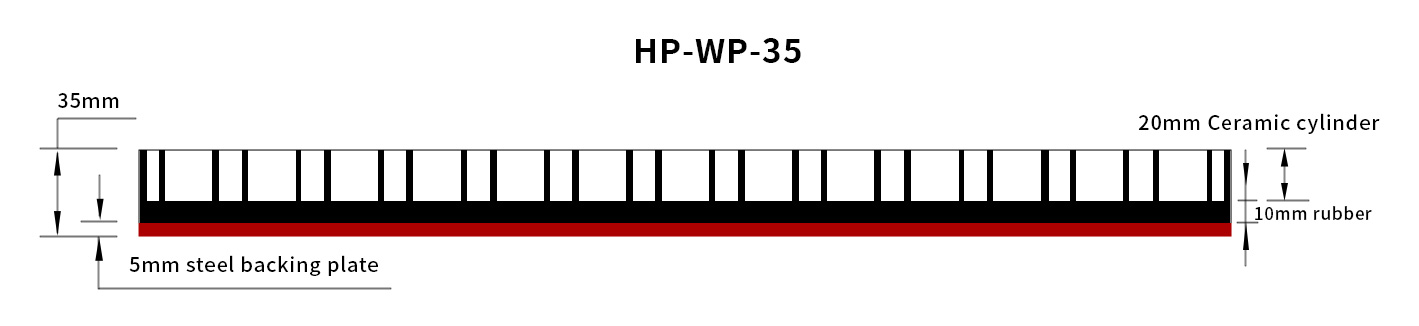

Ceramic Liner | HP-WP-35 | 35mm | Ø20*20 MM | 500*500mm |

Ceramic Liner | HP-WP-75 | 75mm | Ø20*20 MM | 500*500mm |

APPLICATION RANGE

Wide industry use: Suitable for thermal power, steel, metallurgy, coal, mining, chemical, cement, and port terminals.

Specific applications: Used in conveying system chutes, powder systems, ash and dust removal systems, and other machinery subject to significant wear.

KEY BENEFITS

Enhanced durability: Reduces wear and tear on equipment, extending its lifespan.

Cost-effective: Lowers operational and maintenance costs.

Versatile and adaptable: Can be customized to meet specific industrial needs.