Conveyor systems are vital in industries such as mining, bulk material handling, and manufacturing, where their efficiency directly impacts productivity. A key challenge for these systems is maintaining proper belt alignment, as misalignment can cause extensive damage, reduce efficiency, and lead to costly downtime. This is where the Vee Return Tracker (also known as the V-Return Tracker) plays a crucial role.

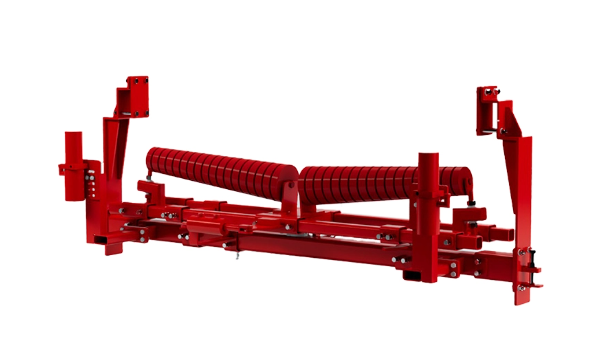

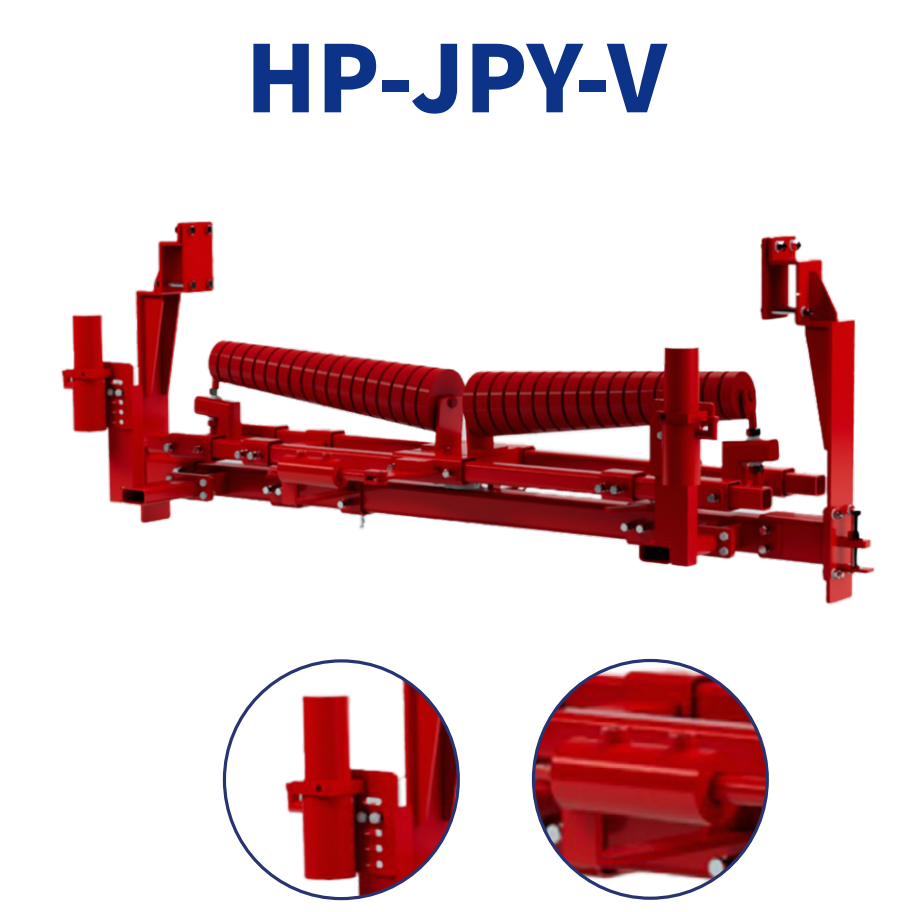

A Vee Return Tracker is a robust, heavy-duty component designed to correct conveyor belt misalignment automatically. By ensuring that the belt remains centered, the system prevents damage to both the conveyor belt and the entire conveyor system. The HP-JPY-V Vee Return Tracker, for example, offers enhanced performance, reduces downtime, and increases plant productivity by offering an efficient, low-maintenance solution. In this article, we will explore how the Vee Return Tracker works, its key benefits, applications, and why it’s an essential addition to any heavy-duty conveyor system.

What is a Vee Return Tracker?

The Vee Return Tracker is an industrial tracking unit used in conveyor systems to correct belt misalignment, specifically on the return side (underside) of the conveyor belt. It is equipped with a V-shaped frame that supports the belt and uses pivoting, tapered rollers to steer the belt back to the center when it drifts off-course. The V-Return Tracker automatically adjusts the belt alignment by responding to changes in the belt's position, which helps maintain smooth, continuous operation.

This technology is typically used in industries where conveyor systems operate in challenging conditions, such as in mining, bulk material handling, or any high-load, high-demand systems. The Dynamic Vee Return Tracker is engineered to handle rugged environments, ensuring minimal downtime and reducing the need for frequent manual adjustments.

How the Vee Return Tracker Works

V-Shape Design

The V-shaped frame is at the core of the Vee Return Tracker’s design. This frame provides the foundation for the belt's return side, ensuring it stays centered. The V-shape helps the system easily guide the belt, especially when it shifts or drifts off-center. The frame’s angled structure keeps the belt on track, supporting it as it moves along the conveyor system.

Tapered Rollers

One of the standout features of the Vee Return Tracker is the use of tapered rollers mounted on a central pivot within the V-frame. These rollers are specifically designed to adjust to the direction of the belt, creating the necessary friction to guide the belt back to the center when it deviates. The tapered design ensures smooth and efficient operation, as the angle of the rollers dynamically changes in response to the misalignment of the belt. When the belt drifts, the speed differential between the rollers activates the pivot, automatically steering the belt back to its correct position.

Automatic Steering Mechanism

The key advantage of the Vee Return Tracker is its ability to automatically correct belt misalignment without the need for manual intervention. When the belt begins to shift off-center, the pivoting tapered rollers work together to correct its path. This automatic steering function makes the tracker highly efficient, as it continuously adjusts to changes in belt position in real-time, ensuring that the belt remains centered throughout its journey along the conveyor.

Heavy-Duty Construction

The Vee Return Tracker is designed for heavy-duty applications and built to withstand tough environmental conditions. The rollers are often equipped with sealed bearings that help protect against dirt, dust, and moisture, which can wear out components over time. Additionally, the tracker features durable lagging made from materials like rubber or polyurethane, which are known for their ability to endure harsh conditions, including wet, dry, or underground environments. This durability ensures that the tracker performs reliably over extended periods, reducing maintenance needs and increasing the lifespan of the conveyor system.

Key Benefits of the Hydraulic Vee Return Tracker

At Hanpeng, we provide the Hydraulic Vee Tracker Roller System, an innovative, power-free solution engineered for precise and automatic conveyor belt alignment. Designed to operate reliably in the most demanding or hazardous environments, this system utilizes advanced hydraulic logic and a robust mechanical structure to ensure continuous, maintenance-free belt centering without the need for external electricity.

1. Instant Correction & Prevention of Belt Damage

The system is designed for immediate response; the moment the belt deviates and touches the detection wheel, the tracker activates. By quickly rotating the self-aligning idler to a corrective angle, it prevents the edge wear and structural damage common in misaligned systems, significantly extending the lifespan of your conveyor belt.

2. No Power Required & Explosion-Proof Safety

One of the core advantages of Hanpeng’s system is its completely passive operation. It requires no electrical power or control components, making it inherently safe for:

Explosion-proof areas and underground mines.

High-temperature, humid, or extremely dusty environments.

Hazardous sites with flammable materials where electrical sparks must be avoided.

3. Enhanced Driving & Energy Efficiency

By replacing conventional driving rollers with high-kinetic vertical rollers, the system captures more energy from the deviating belt. This energy is efficiently transmitted to the hydraulic oil pump, providing a more powerful and decisive correction force than traditional mechanical trackers, even for heavy-duty applications.

4. High Durability & Low Maintenance

The Hydraulic Vee Tracker is built for longevity. All hydraulic components operate under extremely low loads and only for short durations when correction is necessary.

Simple structure: Minimal moving parts reduce the risk of mechanical failure.

Rational Layout: With one set installed every 20-50 meters, the system provides comprehensive protection across the entire conveyor line with minimal upkeep requirements.

Common Applications of the Hydraulic Vee Return Tracker

1. Mining & Coal Industries (Underground & Surface)

In the mining sector, conveyor systems are the lifeline of production. Our hydraulic tracker is ideal for longwall or track-shifting conveyors that operate in:

Underground Mines: Where explosion-proof equipment is mandatory due to flammable gases.

Harsh Environments: Effectively handles wet, muddy, or high-dust conditions common in coal extraction and transport, reducing the risk of costly breakdowns.

2. Power Generation & Metallurgy

Reliability is critical in continuous-operation plants. The system’s ability to withstand high temperatures makes it perfect for:

Power Plants: Aligning belts in high-heat zones near furnaces or boiler feed systems.

Metallurgical Facilities: Managing heavy loads of ore and metal concentrates where equipment must endure extreme heat and abrasive dust without electrical failure.

3. Chemical Engineering & Petrochemical Workshops

In environments with high concentrations of volatile chemicals or explosive materials, electrical components pose a significant safety risk.

4. Bulk Material Handling, Ports & Building Materials

For large-scale infrastructure projects, material loss and belt wear lead to massive overheads. This system is widely used in:

Ports & Terminals: Handling high-speed loading of sand, gravel, and minerals.

Cement Plants: Operating reliably in extremely dusty environments where standard electronic sensors often fail.

Long-Distance Conveyors: By installing units every 20-50 meters, it ensures the belt remains centered across kilometers of terrain, even under heavy-duty loads.

Conclusion

The Vee Return Tracker is a crucial component for ensuring conveyor systems run smoothly and efficiently. However, it is just one part of Hanpeng’s extensive portfolio. We offer a comprehensive range of Tracker Roller Systems, including the high-performance HP-JPY-C Hydraulic Dynamic Trough Tracker, designed to handle the most demanding alignment challenges.

To provide a truly one-stop solution, Hanpeng also supplies a full suite of high-quality accessories, such as standard Idler Rollers, like Polyurethane Tapered Idler Rollers, and Polyurethane Cylindrical Idler Rollers. Whether you are looking for specific components or a complete system overhaul, Hanpeng’s integrated approach reduces maintenance costs and ensures long-term operational reliability.