Conveyor belt systems are critical in various industries, including mining, cement, and manufacturing, where bulk materials are moved across long distances. One of the essential components of these systems is the Primary Scraper, a key part of Belt Cleaning Systems that ensures optimal performance and reduces downtime.

A Primary Belt Scraper works in conjunction with secondary cleaning systems to efficiently remove carryback (material that sticks to the conveyor belt) from the belt surface, maintaining cleanliness and efficiency. In this article, we’ll explore the importance of Primary Scrapers and why they are critical to conveyor belt maintenance.

What is a Primary Scraper?

A Primary Scraper is designed to remove the bulk of the material that sticks to the conveyor belt during operation. Typically installed at the head pulley or discharge point, Primary Belt Scrapers are the first line of defense against material carryback.

Primary Scrapers are often made of durable materials like polyurethane or tungsten carbide, which can withstand the harsh conditions of conveyor systems and offer long-lasting performance.

Core Functions of Primary Scrapers

Removing Bulk Material Carryback

One of the primary functions of the Primary Scraper is to remove bulk material carryback, which can otherwise lead to significant material buildup on the return side of the conveyor belt. The scraper works by using a blade that comes into contact with the belt surface, scraping off any residual material as the belt moves.

Preventing Buildup on Return Side

When material accumulates on the return side of the belt, it can cause misalignment, premature wear, and even damage to the conveyor system. A Primary Belt Scraper ensures that material carryback is minimized, allowing for smoother operation and reducing the need for costly repairs.

Operational Benefits

Enhancing Conveyor Efficiency

A clean conveyor belt operates more efficiently, allowing for the smooth transportation of materials without unnecessary interruptions. The Primary Scraper ensures that carryback is removed quickly, preventing disruptions in the material flow and minimizing the risk of blockages.

Reducing Maintenance Costs

By preventing material buildup and reducing wear on the conveyor belt, a Primary Scraper reduces the need for manual cleaning and costly repairs. The scraper also helps in preventing damage to the belt, pulleys, and other conveyor components.

Extending Belt and Equipment Life

Regular use of a Primary Scraper extends the life of both the belt and the overall conveyor system. By reducing abrasive damage and maintaining the belt’s integrity, the scraper ensures that the conveyor system runs smoothly for a longer period, reducing the need for frequent replacements.

Safety, Environmental, and Quality Advantages

Reducing Workplace Hazards

One of the biggest safety risks in conveyor operations is the potential for spills and slipping hazards due to material carryback. The Primary Belt Scraper significantly reduces these risks by keeping the conveyor belt clean and free of excess material.

Minimizing Environmental Impact

With the ability to reduce carryback, the Primary Scraper also minimizes the environmental impact associated with excess material spilling onto the ground. This is especially important in industries where waste reduction is a key concern.

Maintaining Product Quality

In industries where product integrity is essential, such as food or pharmaceuticals, a Primary Scraper ensures that no unwanted contaminants are transferred from the belt to the product, preserving the quality of the material being transported.

Best Practices for Maintenance

To get the most out of a Primary Belt Scraper, it is essential to implement regular maintenance practices, such as checking for wear and tear, adjusting tension, and replacing the blade when necessary. By keeping the scraper in top condition, you can ensure that your Belt Cleaning System works efficiently and effectively.

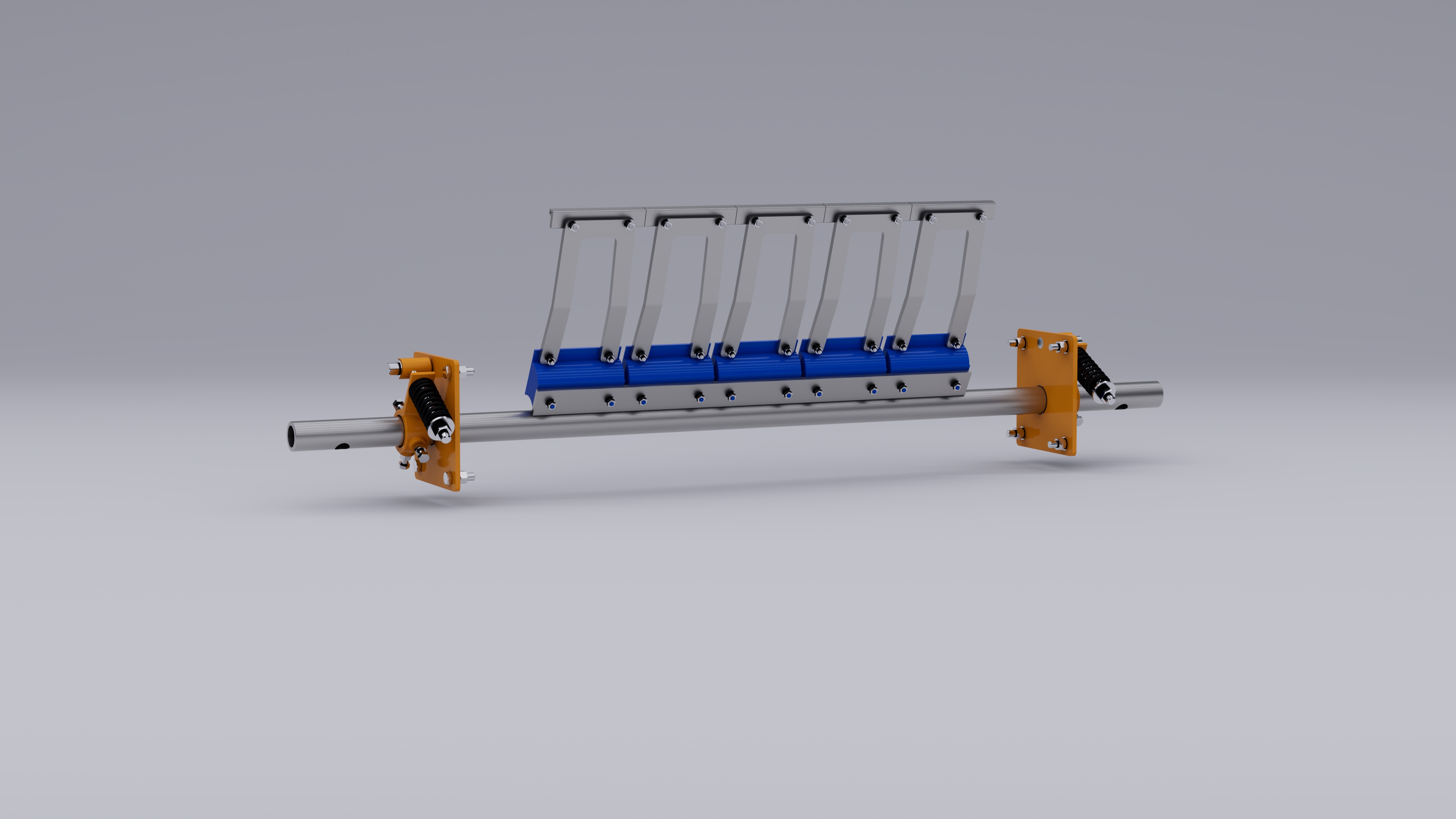

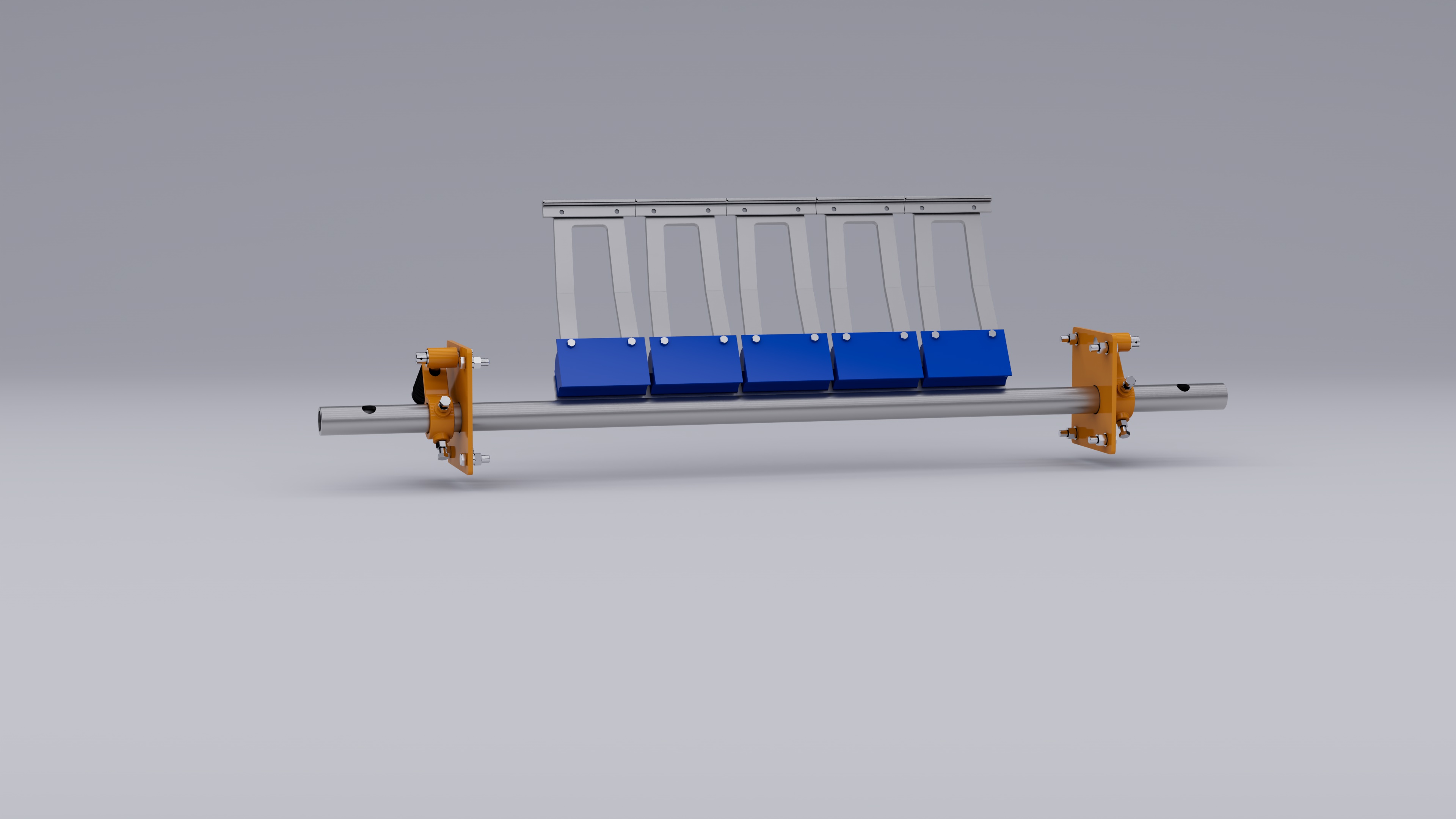

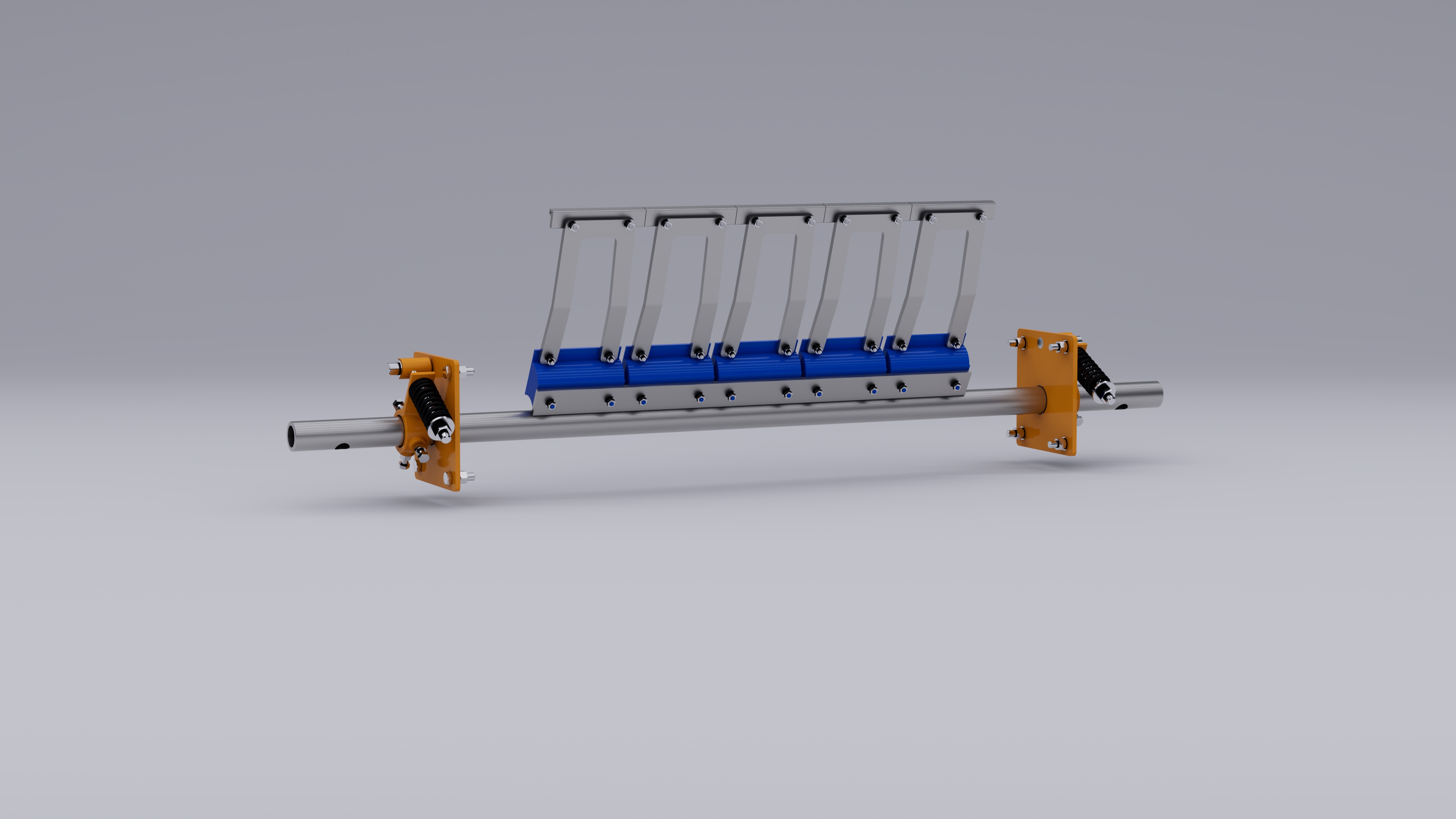

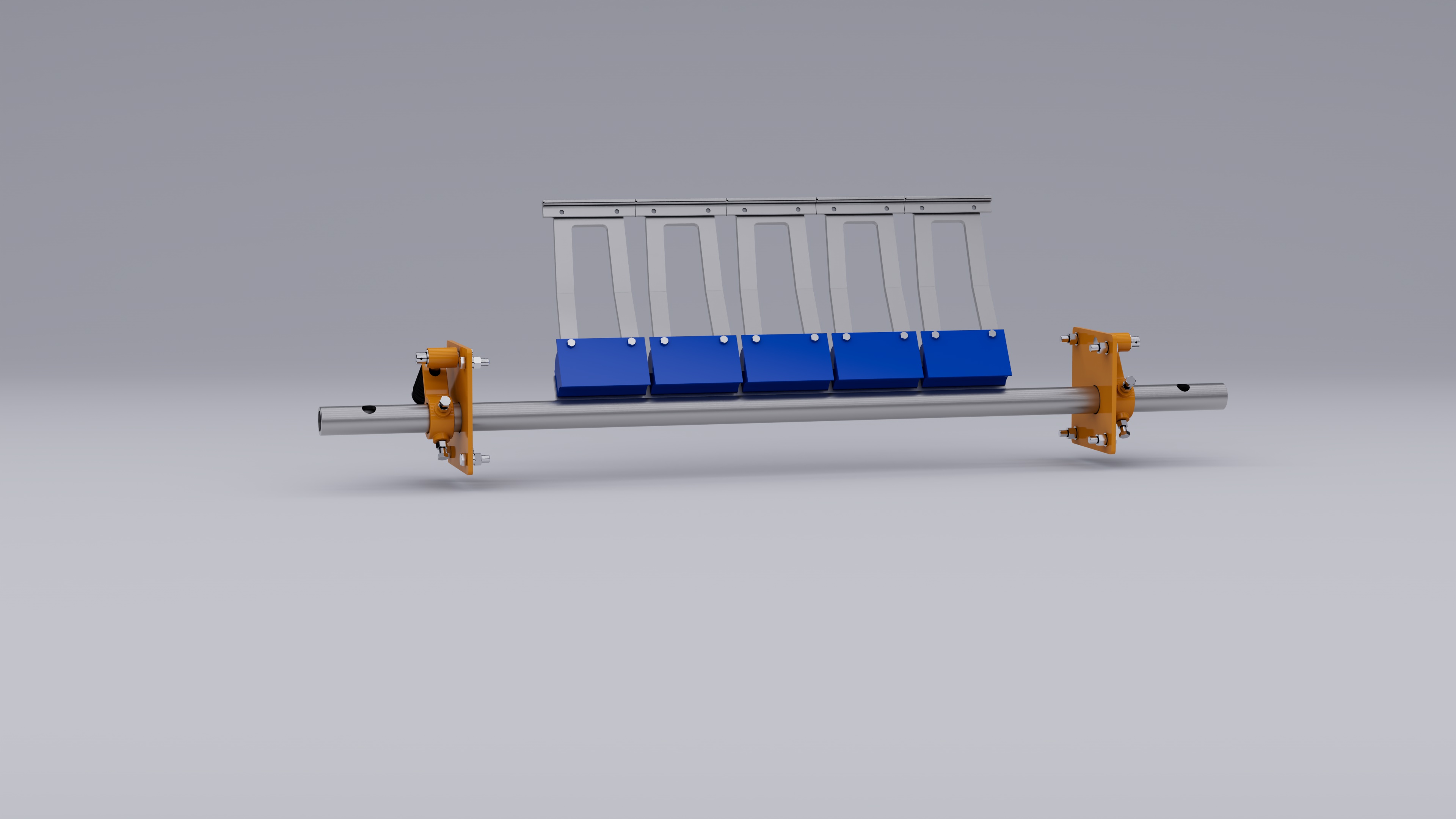

HP-F2: A Reliable Primary Scraper Solution by Hanpeng

At Hanpeng, we understand the critical role that Primary Scrapers play in maintaining conveyor systems. That's why we offer the HP-F2 Primary Scraper, an advanced and durable solution designed to handle the most challenging conveyor environments. The HP-F2 features high-quality materials like tungsten carbide and polyurethane, ensuring long-lasting performance even under harsh conditions.

Key Features & Advantages:

Modular Tungsten Carbide Blades: Easy to replace, reducing maintenance costs and downtime.

High-Hardness Tungsten Carbide: Provides long-lasting performance even in harsh conditions.

Natural Rubber Base: Cushions and reduces friction, extending the life of both the belt and scraper.

Galvanized Frame: Increases strength and corrosion resistance, ideal for harsh environments.

Adjustable Tensioner: Dual-spring system allows precise blade pressure adjustment for optimal cleaning.

Model & Bandwidth Correspondence

To ensure optimal performance, the HP-F2 scraper is available in various models suited for different conveyor belt widths. The following are the corresponding models for each belt width:

B-800: Applicable to a belt width of 600mm

B-1000: Applicable to a belt width of 800mm

B-1200: Applicable to a belt width of 1000mm

B-1400: Applicable to a belt width of 1200mm

B-1600: Applicable to a belt width of 1400mm

B-1800: Applicable to a belt width of 1600mm

B-2000: Applicable to a belt width of 1800mm

B-2200: Applicable to a belt width of 2000mm to 2400mm

This variety ensures that no matter the size of your conveyor system, the HP-F2 scraper can be customized to fit your specific needs.

Key Operational Conditions:

Clearing Fine Particles: The Primary Scraper is highly effective in removing fine particles like coal dust, mineral sands, and similar materials, preventing them from accumulating on the conveyor belt.

Handling High Moisture or Muddy Materials: The scraper is designed to handle wet, sticky, or muddy materials, which are often difficult to remove without a powerful scraper solution.

Cleaning Accumulated Material at Head Pulley or Discharge Points: The HP-F2 scraper efficiently removes material buildup from the head pulley or discharge point, where material is most likely to accumulate.

Suitable for One-Way Conveyor Systems: The HP-F2 is perfect for one-way conveyor systems, where the material flow is unidirectional and a reliable scraper is required to keep the belt clean.

Industries Served:

Coal Industry: In the coal industry, the Primary Scraper helps in handling coal dust and fines, which are often problematic when left on the belt. The scraper minimizes the risk of accumulation and ensures the smooth operation of conveyor systems.

Steel Manufacturing: The steel industry often involves the transportation of heavy, abrasive materials. The HP-F2 scraper is designed to handle such materials, ensuring minimal wear on the conveyor belt and extending the system's lifespan.

Mining: Whether in the extraction of ores or transporting mined materials, Primary Scrapers are crucial in ensuring that no valuable minerals are lost due to carryback, particularly when working in harsh conditions.

Fertilizer and Building Materials: In these industries, where bulk materials like sand, gypsum, or fertilizers are transported, the HP-F2 scraper ensures the removal of any residual material from the conveyor belt, maintaining cleanliness and preventing contamination.

Cement Production: Cement plants involve the handling of fine powders and aggregates, which can accumulate on conveyor belts and cause inefficiencies. The Primary Scraper is essential in removing these materials and ensuring smooth operation.

Conclusion

The Primary Scraper providing a multitude of benefits, including enhanced efficiency, reduced maintenance costs, and improved safety. By maintaining your primary scraper and integrating it with secondary cleaning systems, you can significantly extend the life of your conveyor belt and ensure smooth operation for years to come.

Beyond Primary Scrapers, Hanpeng also offers a full range of conveyor belt cleaning products, including Secondary Scrapers, Belt Cleaning Brushes, Belt Return Side Scrapers, and Pulley Cleaners. In addition to these, we provide a variety of high-quality conveyor accessories. Whether you need specific components or a complete system upgrade, Hanpeng’s integrated solutions reduce maintenance costs and ensure long-term reliability in your operations.