In any belt conveyor system, lagging plays a key role in optimizing efficiency and reducing wear. But which material is best for your needs—Polyurethane or Ceramic Lagging? Both offer unique advantages, but the right choice depends on your system’s specific requirements.

In this article, we’ll explore the benefits and limitations of both options. You’ll learn how to choose the best lagging for your conveyor system to boost performance and extend its lifespan.

What is Lagging and Why Does It Matter for Your Conveyor System?

Overview of Lagging in Conveyor Systems

Lagging refers to a material layer that is bonded to the surface of the conveyor pulley to increase friction, reduce wear, and protect the pulley from environmental elements. It enhances the performance of the belt conveyor system by providing better traction and reducing the chances of belt slippage.

When choosing lagging, it's essential to select a material that meets the specific requirements of the conveyor system, such as the type of material being handled, pulley type, and environmental factors like temperature and moisture. A well-chosen lagging material can prolong the life of your conveyor system and reduce maintenance costs.

Common Types of Lagging Materials

There are several lagging materials commonly used in conveyor systems:

● Rubber Lagging: Typically used for general applications, it provides good protection against wear and offers a smooth surface.

● Polyurethane Lagging: Known for its durability, abrasion resistance, and ability to withstand harsh conditions. It is often used in non-drive pulleys or areas where slippage is a concern.

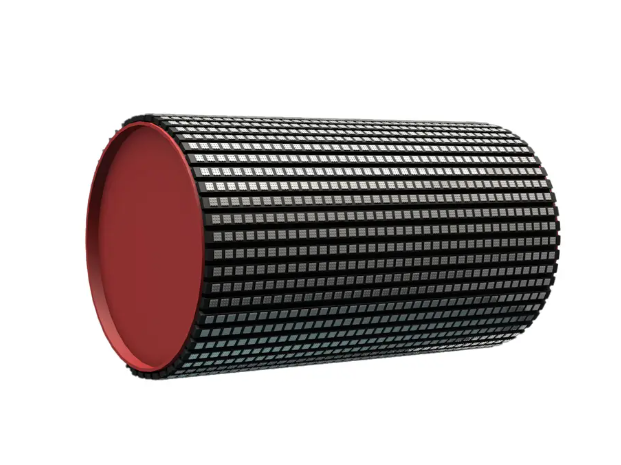

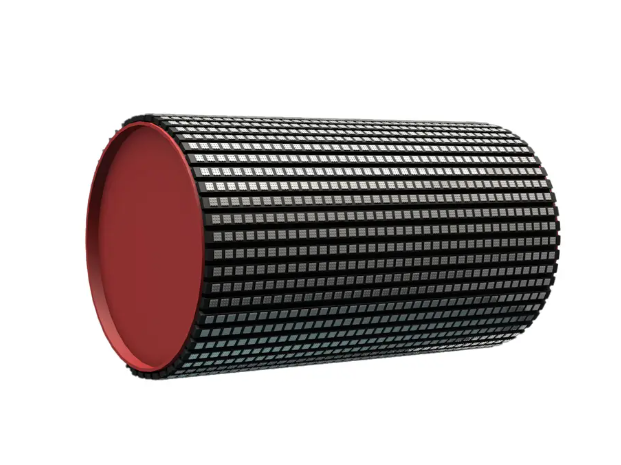

● Ceramic Lagging: Offers superior abrasion resistance and is ideal for high-wear environments. Ceramic tiles are often applied to improve traction and reduce slippage.

Each material has its strengths, and the right choice depends on factors such as load type, pulley type, and conveyor design.

Polyurethane Lagging: Advantages and Limitations

Why Choose Polyurethane Lagging?

Polyurethane lagging has gained popularity, particularly in applications where there are concerns about carryback build-up between the belt and the lagging surface. Polyurethane is highly resistant to abrasion, offering a lifespan that is 3 to 5 times longer than rubber. It also has a low friction coefficient, making it ideal for use on bend pulleys where slippage between the belt and lagging is common.

Additionally, the low friction of polyurethane reduces wear on the belt cover, which is crucial for preventing premature belt damage.

Disadvantages of Polyurethane Lagging

Despite its many advantages, polyurethane lagging does come with some drawbacks. First, it is costly to apply, especially in the case of cast polyurethane. It is also difficult to repair, making it a less flexible choice compared to rubber or ceramic lagging.

Polyurethane lagging typically has a lifespan of about five years before the pulley requires refurbishment, which means it is not the most cost-effective solution for long-term use. Due to the high cost and intensive labor involved in maintenance, it is recommended to use polyurethane lagging only in non-drive pulleys or on bend pulleys in turnover conveyors.

Cost Considerations and Application Scenarios

When considering polyurethane lagging, it’s essential to factor in both initial installation costs and long-term maintenance. While it can significantly increase the lifespan of a pulley, the high cost of installation and the need for periodic refurbishment should be taken into account.

Application Scenarios:

● Non-drive pulleys

● Bend pulleys

● Areas with slippage concerns

Ceramic Lagging: The Durable Alternative

Why Ceramic Lagging Is Popular

Ceramic lagging is a highly durable solution, especially in environments where wear and tear are significant concerns. The ceramic tiles used in lagging are known for their excellent abrasion resistance, making them ideal for handling harsh materials like gravel, coal, or other bulk materials. Ceramic lagging offers increased traction, reducing the chances of belt slippage, particularly on drive pulleys.

What makes ceramic lagging stand out is its ability to be customized in terms of ceramic coverage. Options like 13%, 39%, and 80% ceramic coverage allow you to tailor the lagging to the specific needs of your conveyor system.

Benefits of Ceramic Lagging for Your Conveyor System

One of the primary advantages of ceramic lagging is its longevity. Ceramic lagging typically lasts more than 20 years in most applications, which is significantly longer than polyurethane. This extended service life can help reduce overall operating costs by minimizing the need for frequent replacements or repairs.

Ceramic lagging also helps improve the efficiency of your conveyor system by providing a smooth or dimpled surface that enhances the grip and tracking of the belt. It is especially beneficial for drive pulleys and high-wear environments.

Potential Drawbacks and Installation Considerations

While ceramic lagging offers numerous benefits, there are also some potential drawbacks to consider. For instance, the dimpled ceramic tiles can cause damage to the belt’s bottom cover if slippage occurs. This is a risk if the pulley system isn’t optimized, so it is important to evaluate the potential for belt slippage before choosing this type of lagging.

Additionally, the installation of ceramic lagging can be more complex than other types, and expert advice is often necessary to ensure the right type of ceramic lagging is selected for your system.

Application Scenarios:

● High-wear environments

● Drive pulleys

● Applications requiring extended service life

Comparing Polyurethane and Ceramic Lagging: Which is Right for You?

Long-Term Cost Effectiveness

One of the most critical factors in choosing between Polyurethane Lagging and Ceramic Pulley Lagging is cost. Although polyurethane has a lower initial installation cost, it needs to be replaced or refurbished every 5 years. On the other hand, ceramic lagging typically lasts 20+ years, making it a more cost-effective solution in the long run.

When considering the total cost of ownership, ceramic lagging provides better value, as it reduces the frequency of replacements and offers superior durability.

Performance in Different Conveyor Systems

The choice between polyurethane and ceramic lagging often depends on the specific requirements of your conveyor system. Ceramic lagging is ideal for high-wear applications and drive pulleys, where maximum traction and durability are needed. Polyurethane, however, is well-suited for non-drive pulleys and environments where slippage is a concern.

Maintenance and Repair Considerations

Both types of lagging require periodic maintenance, but ceramic lagging generally requires fewer replacements and less frequent maintenance than polyurethane. While polyurethane can be difficult and costly to repair, ceramic lagging’s long lifespan and robustness make it a more maintenance-friendly option over time.

Key Factor | Polyurethane Lagging | Ceramic Pulley Lagging |

Long-Term Cost Effectiveness | Lower initial installation cost, but needs replacement every 5 years. | Lasts 20+ years, making it more cost-effective in the long run. |

Performance in Different Systems | Best for non-drive pulleys and environments with slippage concerns. | Ideal for high-wear applications and drive pulleys, offering maximum traction and durability. |

Maintenance and Repair | Requires frequent maintenance, difficult and costly to repair. | Requires less frequent maintenance, offering a more maintenance-friendly solution with fewer replacements. |

Expert Insights: Choosing the Right Lagging for Your Conveyor System

Assessing Your Conveyor's Needs

Choosing the right lagging material requires careful evaluation of your conveyor system's needs. Key factors include the conveyor design, pulley type, belt speed, and material handling characteristics. Additionally, it’s essential to assess environmental factors such as temperature, moisture, and abrasive materials.

Consulting Experts for Optimal Decision-Making

Expert advice is crucial when selecting lagging material for your system. An experienced professional can assess your system’s unique conditions and recommend the most suitable material. This can help you avoid costly mistakes and ensure that your conveyor system operates at maximum efficiency.

Conclusion

In conclusion, both Polyurethane Lagging and Ceramic Lagging offer distinct advantages and can be the right choice depending on your system’s specific needs. Polyurethane is ideal for non-drive pulleys and environments with slippage concerns, while ceramic lagging is the superior choice for high-wear applications and drive pulleys due to its extended service life and durability.

Before making a decision, it’s essential to consult with experts who can help you choose the best lagging material based on your operational requirements and long-term goals.

Hanpeng material Rubber Industry (Liaoning) Co., Ltd. specializes in high-quality conveyor solutions, offering durable ceramic pulley lagging and other products designed to enhance performance and extend equipment life.

FAQ

Q: What is Ceramic Lagging and how does it work?

A: Ceramic Lagging is a layer of ceramic tiles applied to conveyor pulleys to increase friction, improve traction, and reduce slippage. It’s ideal for high-wear environments and provides long-lasting durability.

Q: How does Polyurethane Lagging compare to Ceramic Lagging in terms of durability?

A: While Polyurethane Lagging offers good abrasion resistance, Ceramic Lagging typically lasts 20+ years, making it a more durable choice, especially for high-wear and drive pulleys.

Q: Why should I choose Ceramic Pulley Lagging for my conveyor system?

A: Ceramic Pulley Lagging is highly resistant to abrasion and provides excellent traction, making it the best choice for applications with heavy wear or slippage, especially on drive pulleys.

Q: What are the main benefits of Polyurethane Lagging?

A: Polyurethane Lagging offers superior abrasion resistance, extends the life of the conveyor belt, and is ideal for non-drive pulleys, where slippage is an issue.

Q: What factors should I consider when choosing between Polyurethane and Ceramic Lagging?

A: Consider factors like pulley type, wear conditions, cost, and maintenance. Ceramic Lagging is best for high-wear environments, while Polyurethane Lagging suits non-drive pulleys with slippage concerns.

Q: Is Ceramic Lagging more cost-effective than Polyurethane?

A: While Ceramic Lagging has a higher initial cost, its long lifespan of 20+ years makes it more cost-effective in the long run, reducing the need for frequent replacements compared to Polyurethane.