In industries where conveyor belts are used to transport bulk materials, maintaining belt cleanliness is essential to ensure smooth operations and to prevent material buildup that can lead to operational disruptions. Secondary belt cleaners are specifically designed to remove residual materials from the surface of conveyor belts, making them a crucial part of belt cleaning systems. These scrapers are positioned behind the primary cleaner and ensure any leftover material is efficiently cleaned, which helps maintain the conveyor belt's performance and extends its lifespan.

Among the many types of secondary scrapers, the HP-M3 model stands out due to its high-efficiency performance, robust design, and compatibility with various industrial requirements. The HP-M3 secondary belt cleaner has been engineered to tackle the toughest cleaning challenges, especially in industries such as mining, material handling, and coal transportation. With its advanced features, the HP-M3 ensures that conveyors remain clean, minimizing the risk of operational disruptions.

Key Features and Characteristics of HP-M3

High-Efficiency Cleaning Performance

The HP-M3 belt cleaner is equipped with tungsten carbide-tipped blades, known for their superior hardness and durability. These blades are elastically supported by high-elasticity rubber, which maximizes cleaning efficiency while ensuring an extended service life. The secondary belt cleaner is designed to deliver consistent and effective cleaning even in challenging environments.

Material Compatibility

The HP-M3 scraper is versatile, compatible with a wide range of belt widths (from 600 to 2,400 mm) and suitable for different bulk solids. Whether it's used in the transportation of dry materials or wet and sticky substances, the HP-M3 provides excellent cleaning results. It is effective for multi-ply nylon and steel-cord belts, as well as vulcanized splicing, making it a flexible choice for various applications.

Speed and Belt Width Compatibility

This secondary scraper is capable of handling belt speeds up to 6.5 m/s, which makes it suitable for high-speed conveyor systems. Its adaptability to different belt widths and types ensures that it can be installed in a variety of conveyor configurations, ensuring comprehensive cleaning no matter the operating conditions.

Design and Build

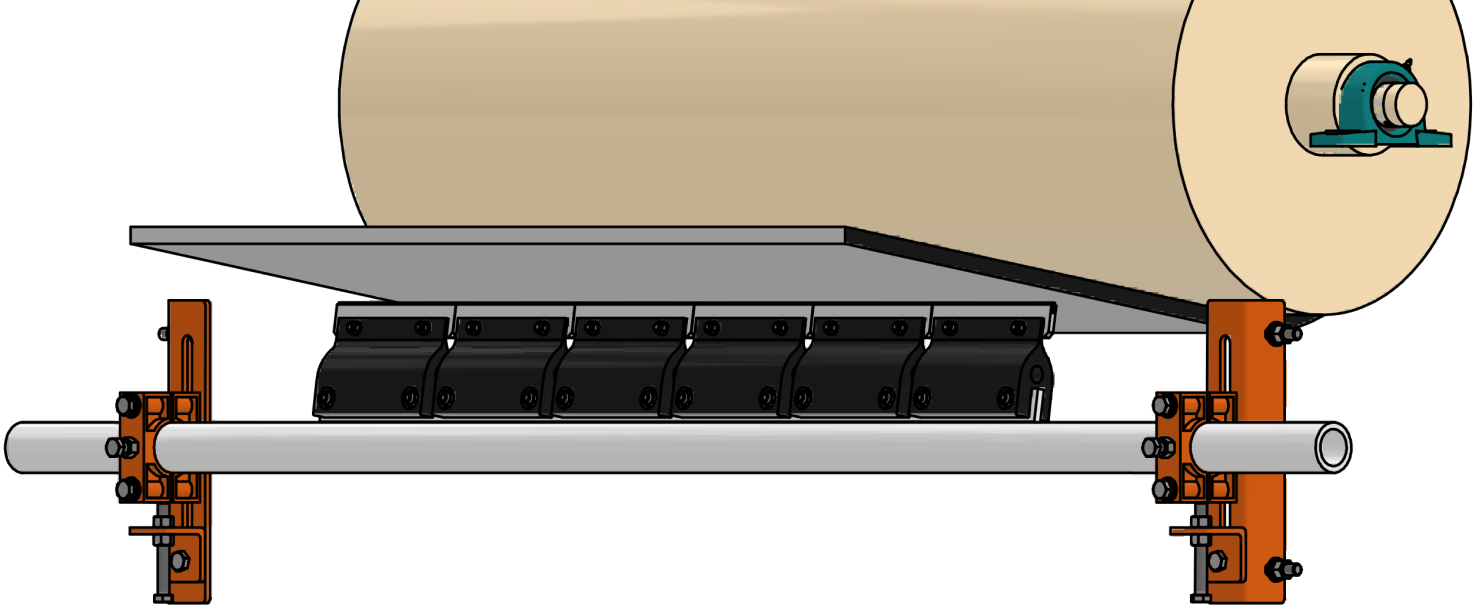

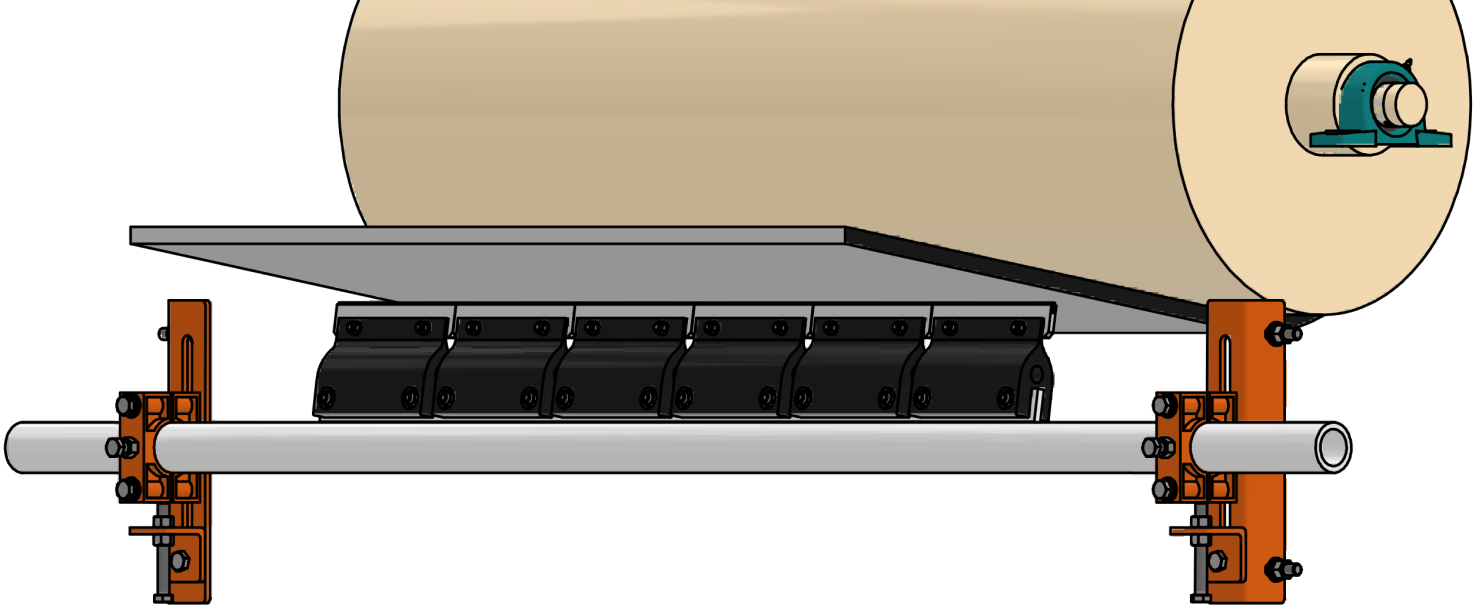

Modular Scraper Design

One of the standout features of the HP-M3 belt cleaner is its modular design. This modular construction allows for easy customization to suit specific conveyor requirements. Each blade module comes with an individual rubber holder to act as a buffer, protecting the tungsten carbide blades from damage and reducing wear. If the cleaning elements wear out, only the individual blades need replacement, which reduces downtime and maintenance costs.

Durability and Service Life

The robust construction of the HP-M3 secondary belt scraper ensures long-term durability and reduced maintenance costs. The tungsten-carbide tips on the blades enhance the scraper's service life by withstanding heavy abrasion. This makes the HP-M3 an ideal choice for industrial operations where the conveyors are exposed to harsh conditions.

Installation and Operation

Easy Installation

Installing the HP-M3 secondary belt cleaner is straightforward and can be done efficiently in various types of conveyor systems. The blade modules are recommended to be positioned 50 - 200 mm behind the vertical position below the pulley. This ensures optimal cleaning, with the blades perpendicular to the belt surface, maximizing the removal of residual material.

Cleaning Module Functionality

Each cleaning module of the HP-M3 belt cleaner is designed to be independent, meaning each blade operates with its own rubber holder as a buffer. This unique design allows the blades to resist impact and continue functioning effectively, even in the most demanding environments. Once the tungsten-carbide cleaning elements are worn, only the individual elements need replacement, which makes it easier and more cost-effective to maintain.

Applications and Use Cases

Industries and Operations

The HP-M3 secondary scraper is ideal for use in industries such as mining, material handling, and coal transport. Its high-efficiency cleaning performance makes it perfect for operations where minimizing material buildup on conveyor belts is crucial. By keeping belts clean, the HP-M3 enhances operational efficiency, reduces downtime, and prevents the costly consequences of carryback.

Effectiveness in Preventing Carryback

Carryback is a common issue in conveyor belt systems where residual materials stick to the belt and eventually fall off further down the line. The HP-M3 belt cleaner is specifically designed to remove this residual material, preventing carryback and ensuring the conveyor belt remains clean. This not only improves operational efficiency but also extends the life of the conveyor system.

General Operating Conditions

Operating Temperatures and Belt Types

The HP-M3 secondary belt scraper operates efficiently within a temperature range of -20°C to +80°C. This broad operating temperature range makes it suitable for use in various environments, from cold storage facilities to high-temperature operations. It is compatible with belts made of rubber or PVC, provided they have a smooth cover plate and a hardness of 60 to 65° Shore A, ensuring reliable cleaning performance in most industrial environments.

Bidirectional Belt Operation

The HP-M3 is designed to support bidirectional belt operation, which is crucial for systems that require movement in both directions. This flexibility enhances its utility in various applications, making it a versatile component in belt cleaning systems.

Conclusion

When you choose the HP-M3 secondary belt scraper, you are opting for a reliable, high-efficiency solution from Hanpeng, a trusted leader in belt cleaning systems. Our professional technical team, with years of expertise in the chemical industry, has developed cutting-edge products designed to reduce maintenance costs and extend the service life of your conveyor systems. In addition to the HP-M3, we offer a wide range of other belt cleaning products to ensure optimal performance in various applications. These include:

Our products are used extensively across industries like mining, cement, electrical power, metallurgy, ports, machinery, petrochemicals, and construction materials. We have built strong technical partnerships with universities and research units, ensuring that we deliver the highest quality solutions for your business needs.