In industries where the smooth operation of conveyor belts is critical to productivity, ensuring that belts stay aligned is paramount. Misalignment can cause significant damage to belts, reduce efficiency, and increase downtime. The Hydraulic Tracker Roller Systems provide an effective solution for keeping conveyor belts centered, optimizing performance, and enhancing safety. These systems are engineered to deliver exceptional durability, high efficiency, and low maintenance—ensuring that your conveyor system runs smoothly and effectively.

Core Features and Benefits of HYDRAULIC TRACKER ROLLER SYSTEMS

The Hydraulic Tracker Roller Systems are designed with cutting-edge technology to provide continuous guidance and support to conveyor belts. The primary features and benefits include:

No Power Source Required & Easy Maintenance

The Hydraulic Tracker Roller Systems operate without the need for any electrical control components or power sources. This feature makes them suitable for explosion-proof, dusty, humid, and high-temperature environments, including hazardous areas with flammable or explosive materials. This also reduces the complexity and costs associated with maintaining electrical systems.

High Reliability & Durability

All components are built to withstand extreme conditions and operate under minimal load for short durations, ensuring excellent reliability and long-lasting durability. They are engineered for consistent performance, providing value over time.

Enhanced Driving Efficiency

The driving roller in the Hydraulic Tracker Roller Systems is replaced with a vertical driving roller. When the conveyor belt deviates, the vertical roller generates greater kinetic energy, which is transferred to the oil pump, offering more power and efficiency compared to conventional systems.

High Correction Efficiency

As soon as the belt deviates, the system activates immediately, rotating the self-aligning idler to correct the deviation. This ensures quick and precise adjustments to keep the belt centered and prevent damage.

Self-aligning Idler Positioning

The self-aligning idler automatically generates an alignment force on the belt. If the idler is not braked, the force disappears, and the system resets. The KLD logic valve group’s braking and positioning function locks the idler at the ideal angle, keeping the belt centered.

Rational Layout for Timely Correction

One set of passive hydraulic deviation-adjusting roller groups is installed every 20-50 meters along the conveyor, ensuring timely correction of any belt deviation and preventing misalignment from causing long-term issues.

Check out the video below to see how our Belt Trackers Machine can benefit your operations

Applications of HYDRAULIC TRACKER ROLLER SYSTEMS

The Hydraulic Tracker Roller Systems are ideal for various industries that rely on conveyor systems, including:

Mining: Prevents damage to belts caused by misalignment in harsh environments.

Cement: Reduces downtime by maintaining efficient belt operation.

Electrical Power: Protects power plant conveyor belts from wear and tear due to misalignment.

Petrochemicals & Construction Materials: Ensures smooth and safe material handling by maintaining belt alignment.

The versatility and high performance of these systems make them suitable for both standard and heavy-duty applications.

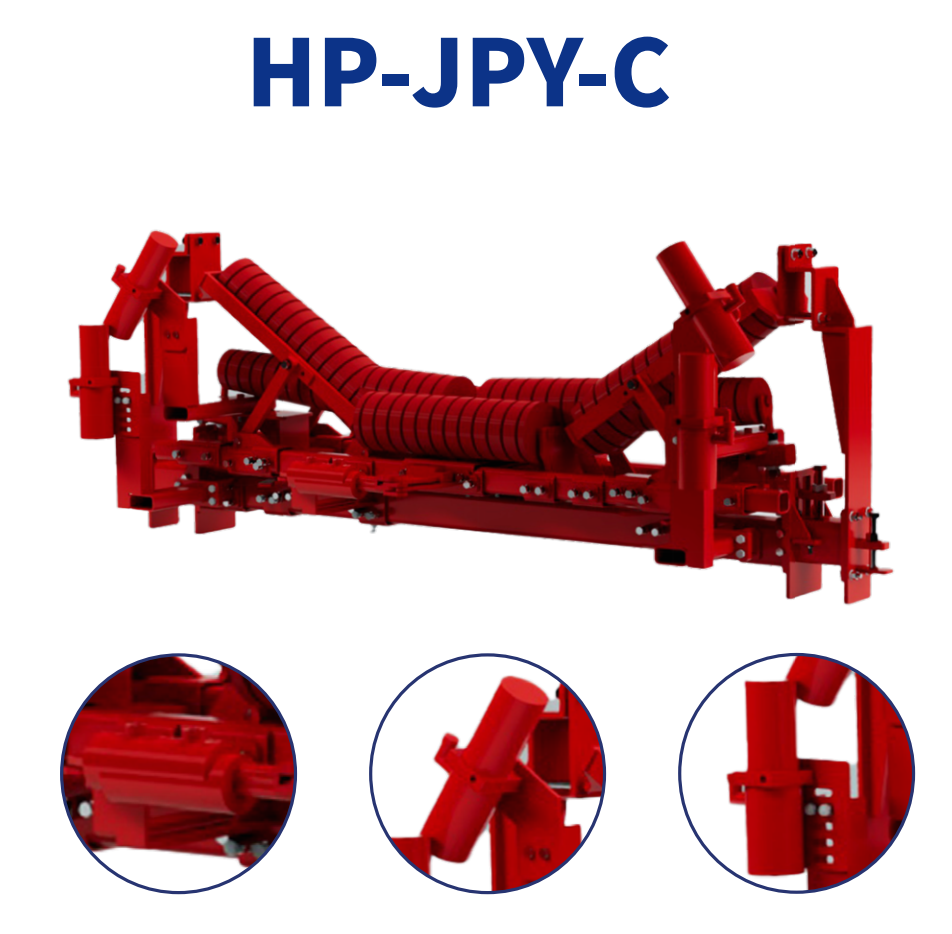

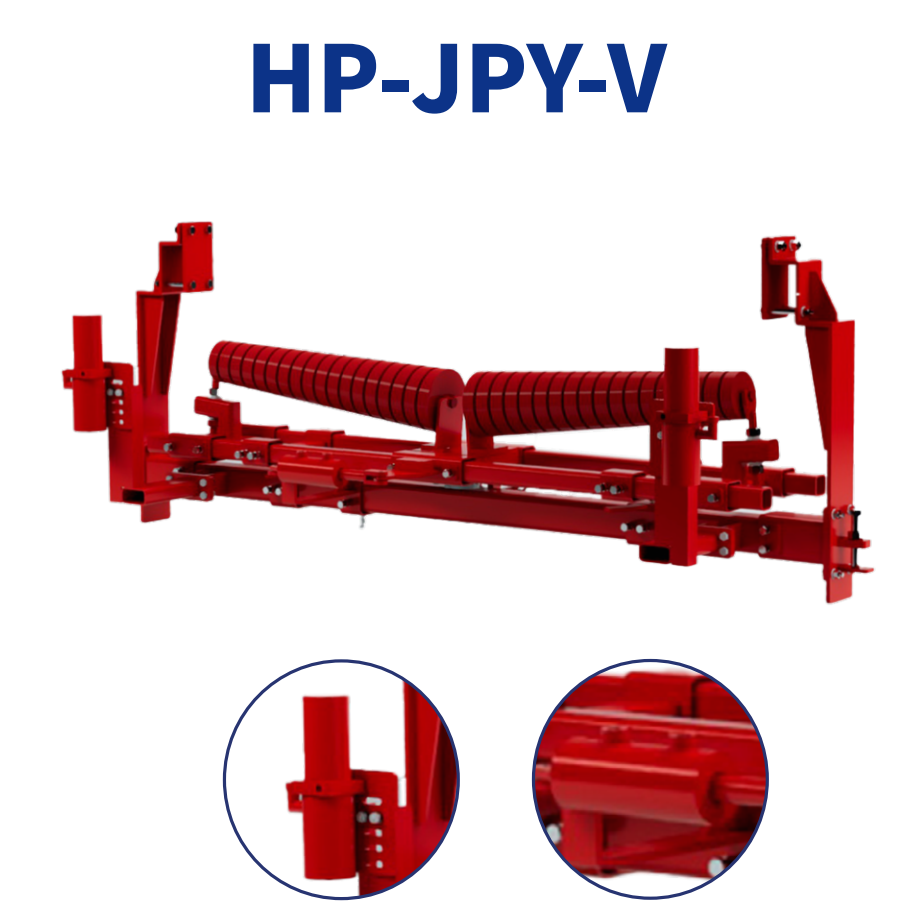

Introducing Our Products: HP-JPY-C and HP-JPY-V

To enhance your conveyor system’s performance further, we offer two premium models of Hydraulic Tracker Roller Systems: the HP-JPY-C and HP-JPY-V. Both models are designed to address different operational needs while offering the same high-level performance, reliability, and durability that our products are known for.

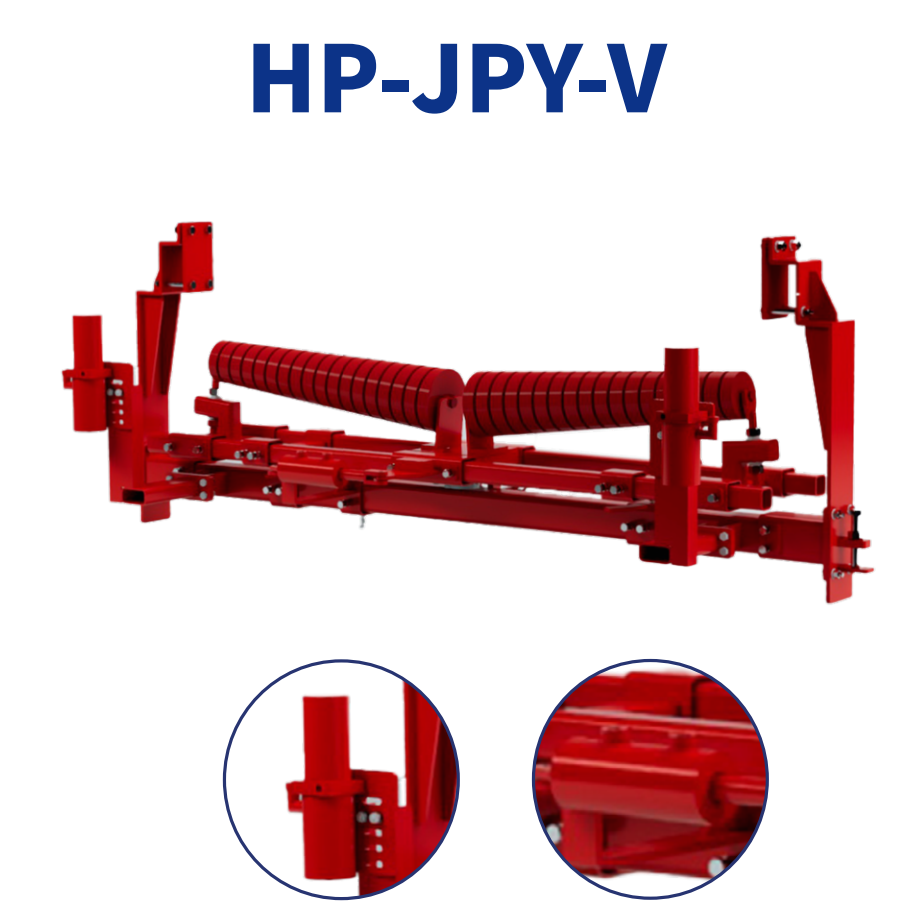

HP-JPY-V

HP-JPY-C

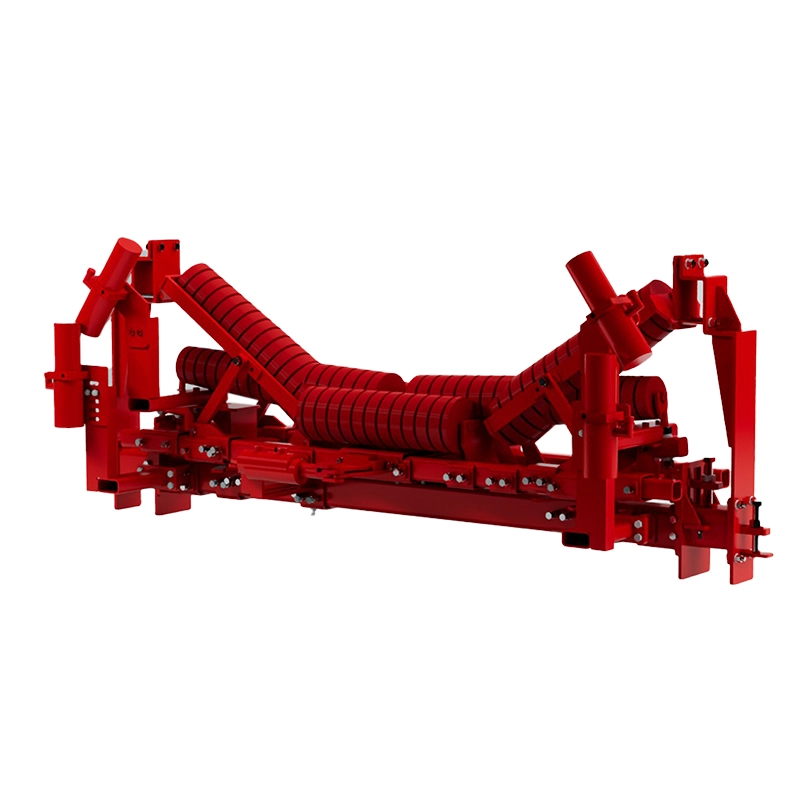

HP-JPY-C – Hydraulic Tracker Roller Systems Dynamic Trough Tracker

The HP-JPY-C model offers continuous guidance and support, ensuring that the conveyor belt stays aligned and operates efficiently.

HP-JPY-V – Hydraulic Tracker Roller Systems Vee Return Tracker

The HP-JPY-V model offers similar features to the HP-JPY-C but is specifically designed for low-height clearance applications, offering more flexibility in tight spaces.

Why Choose Us?

At Hanpeng Material Rubber Industry (Liaoning) Co., Ltd., we are committed to providing the best engineering solutions for conveyor systems. Our products, including the HP-JPY-C and HP-JPY-V, are designed to reduce maintenance costs, improve system reliability, and enhance safety. With years of expertise, we offer tailored solutions for industries worldwide, backed by professional service and high-quality standards.

FAQ

1. What is the main advantage of the Hydraulic Tracker Roller Systems?

The Hydraulic Tracker Roller Systems provide continuous belt alignment without the need for a power source, ensuring smooth, reliable, and safe conveyor operations while reducing maintenance and energy costs.

2. How do Hydraulic Tracker Roller Systems work in hazardous environments?

These systems are designed to operate in explosion-proof, dusty, humid, and high-temperature environments. They do not require electrical components, making them ideal for hazardous areas where conventional electrical systems cannot be used.

3. What makes the HP-YJP-V model suitable for low clearance applications?

The HP-JPY-V is specifically designed for environments with limited space, ensuring reliable performance and alignment correction even in tight areas where standard models might not fit.

4. How do these models reduce downtime and energy consumption?

Both the HP-JPY-C and HP-JPY-V models are built to minimize energy waste and prevent unnecessary downtime through dynamic self-adjusting systems, ensuring that conveyor belts are always properly aligned and running smoothly.